Facing a shrinking engineering workforce and rising costs, machine designers are always looking for ways to build machines faster with fewer resources. As part of our ongoing commitment to simplify motion control, this article explores the innovative features of our new connector-type motors for the AZ Series, which are designed to facilitate faster installation and maintenance.

---

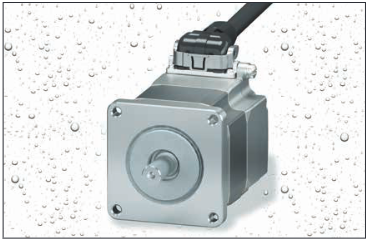

**Image:** [A high-quality image of the AZ Series connector-type motor]

---

### Background:

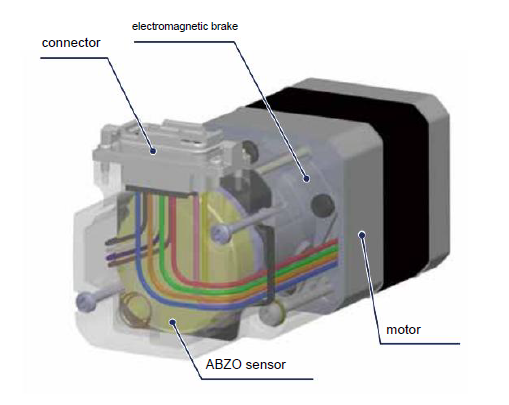

Our customer-facing teams regularly seek feedback to enhance our products. For the AZ Series cable-type motors, which are known for their closed-loop capabilities with AlphaStep hybrid open/closed-loop control technology and a patented built-in mechanical absolute encoder, we received valuable insights from several customers.

- A client using an AZ Series cable-type motor in a test process to address homing accuracy issues caused by thermal expansion of an external photo sensor suggested simplifying cable management by reducing the number of cables.

- Another client, working with a 20mm frame size AZ Series cable-type motor in a tight space, faced challenges with joining cables being too large for the motor connections. They expressed concerns about electrical noise interference and washdown issues due to exposed connectors. A solution to eliminate the middle extension cable was proposed.

- Yet another client, using an AZ Series cable-type motor in LED equipment, needed more flexible cables for internal routing. The rigid section of the cable was problematic, prompting a request for fully flexible cables.

In response to this feedback, Oriental Motor has introduced a **new line of AZ Series connector-type motors**, featuring a novel **flat connector** from Hirose Electric. This design improves usability and incorporates a **consolidated cable** for easier driver connection.

---

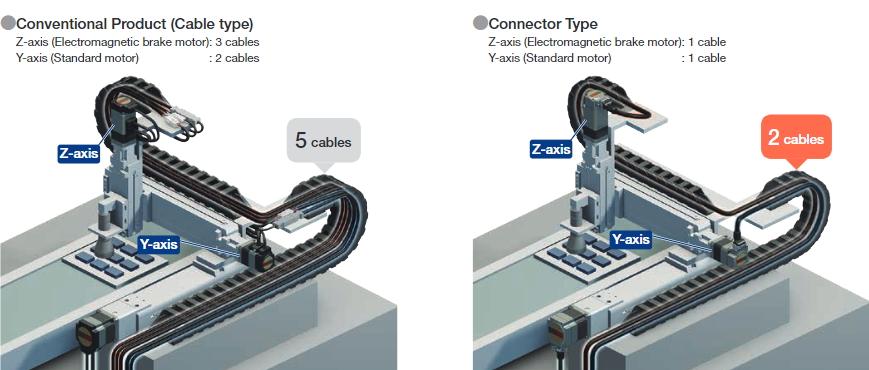

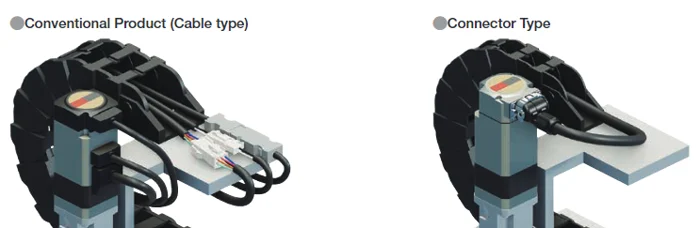

### Standard Cable-Type Motor vs. New Connector-Type Motor:

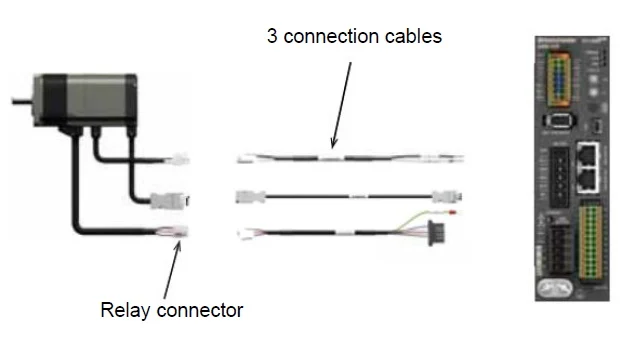

In the **standard cable-type motor**, multiple pigtail cables are used—motor cables, encoder cables, protective earth ground cables, and electromagnetic brake cables (for brake motor types). A middle extension cable is typically required to connect the motor to the driver.

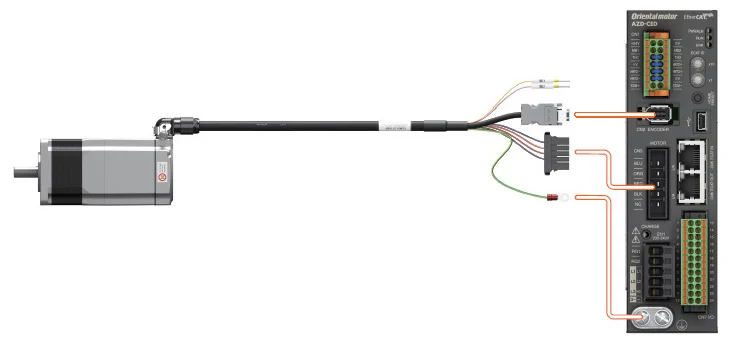

The **new connector-type motor**, however, features an enhanced connector design and consolidates all cables into a single unit. This simplifies the installation process, reduces maintenance needs, and allows the motors to fit into tighter spaces.

---

### Benefits of One-Cable Technology:

#### Unified Cables:

- Reduces routing work and downsizes cable holders.

- Example: A Cartesian system with five cables for the Y and Z axes can be simplified to just two cables. This reduces the size of the cable holder significantly.

#### Direct Connection:

- Eliminates the need for middle joining cables.

- Reduces electrical noise interference (EMI).

| Cable Type | Connection Example |

|------------------|------------------------------------------|

| Cable Type |  |

| Connector Type |  |

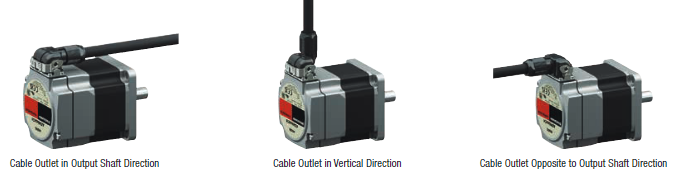

#### Three Cable Outlet Directions:

- Offers flexibility with three configurations: shaft direction, vertical direction, or opposite to the output shaft direction. This is indicated by "F" (front), "B" (back), or "V" (vertical) in the cable part number.

#### Faster Maintenance:

- Simplifies motor replacement and cable management.

- Example: Downsizing the cable track reduces maintenance time.

#### Reduced Material Usage:

- Consolidating cables reduces material usage.

- For example, consolidating three cables into one reduces the cross-sectional area by 44.3% and the mass by 55.5%.

#### Easy Installation:

- Lock lever connectors allow for quick and tool-free connections.

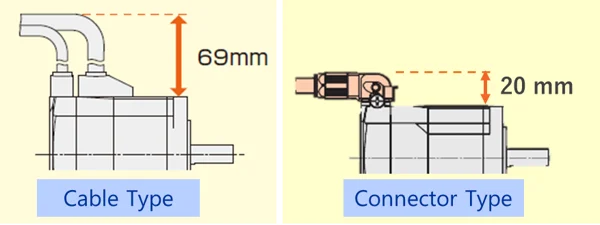

#### Low Profile, Flat Connector:

- The flat connector reduces the motor's height by 49mm compared to the cable type.

#### Maintains High Ingress Protection:

- The connector and cable maintain an IP66 rating, ensuring they can withstand sprayed water jets and dust.

---

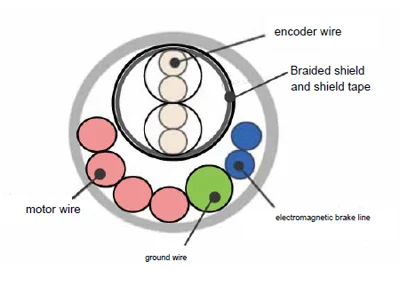

### Addressing Electrical Noise Challenges:

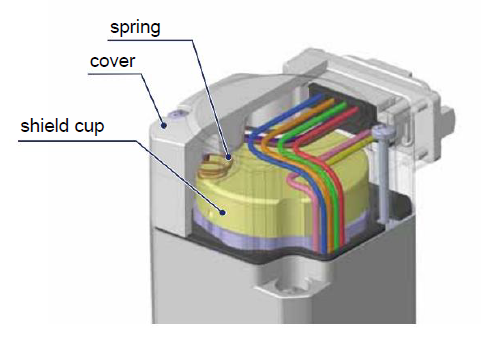

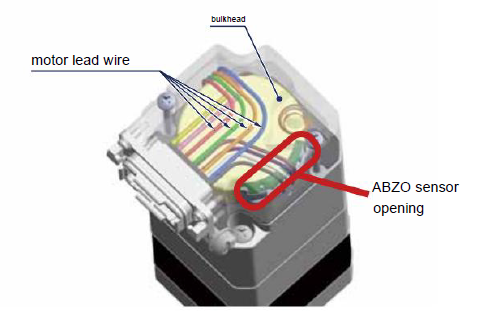

Stepper motors generate radiated noise due to Pulse Width Modulation (PWM) control. To integrate all signals into one cable while preventing electrical noise issues, we redesigned the motor internally and rerouted the motor and electromagnetic brake wires.

To prevent magnetic interference, the built-in mechanical absolute encoder is housed within a steel shield cup. The shield cup and motor casing are electrically grounded using a metal spring, and the sensor opening is sealed.

By grounding the shield cup and motor housing, noise propagation to the ABZO sensor is eliminated, ensuring reliable operation even in noisy environments.

---

### Product Lineup:

The AlphaStep AZ Series connector-type motors are available in 42mm and 60mm frame sizes. More frame sizes will be added over time. The specifications and flange size match those of the traditional cable-type motors, making upgrades seamless.

The connector-type motors can be ordered with various pre-assembled gearhead options, including TS spur gears, right-angle FC face gears, PS planetary gears, and harmonic gears. Future plans include expanding to linear and rotary actuators.

The connector-type motors are compatible with all AZ Series drivers: AC input, DC input, and mini drivers. They support common industrial communication protocols like EtherNet/IP, EtherCAT, and Profinet.

Cable lengths vary depending on the driver type: 1–10 meters for AC input drivers, 0.5–10 meters for DC input drivers, and 0.2–10 meters for mini drivers.

---

### Additional Update: March 18, 2024

We're excited to announce **one more reason to upgrade** to the AZ Series connector-type motors. Released in 2024, these integrated motor driver mounting brackets allow users to attach an AZ Series mini driver directly to the connector-type motor, saving both space and cabling.

These mounting brackets are currently available for 42mm and 60mm frame size connector-type motors.

---

In conclusion, the consolidated cable offers eight key benefits: fewer cables to manage, direct motor-to-driver connection, three cable outlet directions, faster maintenance, reduced material usage, easier installation, a lower-profile flat connector, and maintained IP66 ingress protection. Until wireless motion control becomes a reality, cables will remain essential in motion control systems. By simplifying the AZ Series connector-type motor setup, Oriental Motor aims to make installation and maintenance easier for all engineers involved.

---

**Call to Action:** Learn more about the AZ Series connector-type motors today!

Carpet Jacquard Fabric Machine

All the electronic jacquard machines under this carpet jacquard fabric machine classification could weave various of patterns stably and sufficiently. These jacquard looms are applicable to various of textile weaving looms, such as rapier loom, air jet loom, water jet loom, shuttle loom, projectile loom with any reed width. These digital jacquard machines are compatible with most brand of textile weaving machinery, just like ITEMA, SOMET, SMIT, PICANOL, DONIER, RIFA, TOYOTA, TSUDAKMOA etc.

Carpet Jacquard Fabric Machine,Jacquard Loom Weaving,Jacquard Automatic Loom Machine,Jacquard Lace Machine

JIANGSU S&S INTELLIGENT SCIENCE AND TECHNOLOGY CO., LTD , https://www.ssjacquard.com