Certainly! Here’s the rewritten content in English:

---

Facing a leaner engineering workforce and rising costs, machine designers need ways to build machines faster with fewer resources. Aligned with our ongoing commitment to simplify motion control, this article highlights the innovative features of the new connector type motor for our flagship AZ Series and how it supports faster installation and maintenance.

---

** **

---

**Background**

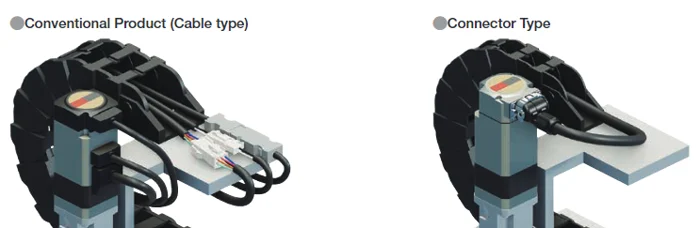

Oriental Motor’s customer-facing teams regularly seek feedback to improve our products. In this case, several customers provided feedback about our AZ Series cable type motors, which are our popular closed-loop motors and drivers featuring AlphaStep hybrid open/closed-loop control technology and a patented built-in mechanical absolute encoder.

- A customer was using an AZ Series cable type motor in a test process to address homing accuracy issues caused by thermal expansion of an external photo sensor. To simplify cable routing, they suggested consolidating the cables between the motors and drivers.

- Another customer was using a 20 mm frame size AZ Series cable type motor to position a stage in a tight space and was using joining cables to extend the cable from the motor to the driver. However, the joining connectors were too large to fit, and they also had concerns about electrical noise interference and washdown risks due to the exposed connectors on the joining cables. To solve these problems, they recommended eliminating the middle extension cable.

- A third customer was using an AZ Series cable type motor for an LED equipment and needed flexible cables for routing around internal components. In the cable type motor, there's a part of the cable that’s not flexible, and they suggested making the entire cable flexible.

In response to this valuable feedback, Oriental Motor has launched a **new line of AZ Series connector type motors** using a new **flat connector** from Hirose Electric to enhance usability and a **consolidated cable** to make it easier to connect to the drivers.

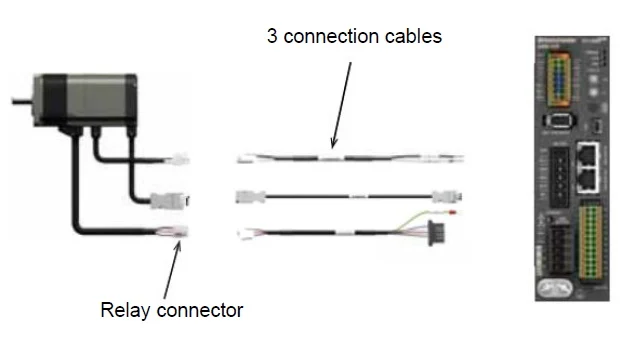

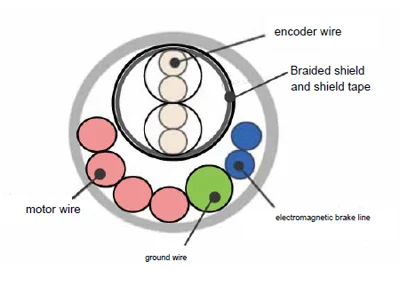

In the **standard cable type motor**, the motor typically has multiple pigtail cables, including those for the motor, encoder, protective earth ground, and electromagnetic brake (for brake motor types). To connect to the driver, a middle extension cable is necessary.

In the **new connector type motor**, we’ve enhanced the design of the connector and combined all the cables into one cable, making these motors easier to use, simpler to maintain, and better suited for tighter spaces.

Let’s take a closer look and explore the advantages the new connector type motors can offer.

---

**Benefits of One Cable Technology**

**Unification of Cables**

- Reduce routing work and downsize cable holders.

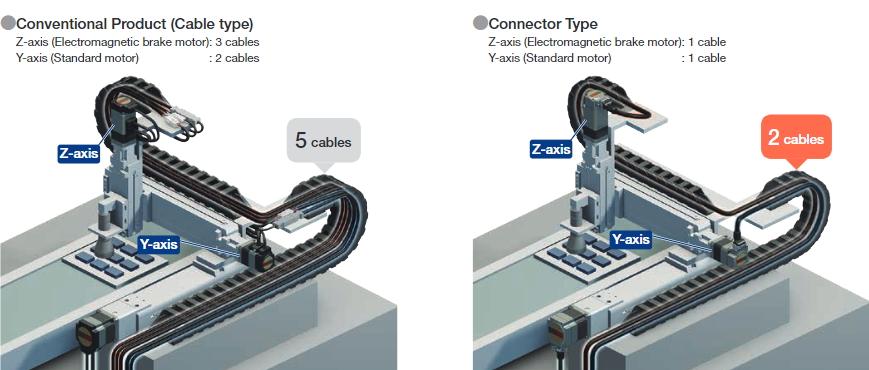

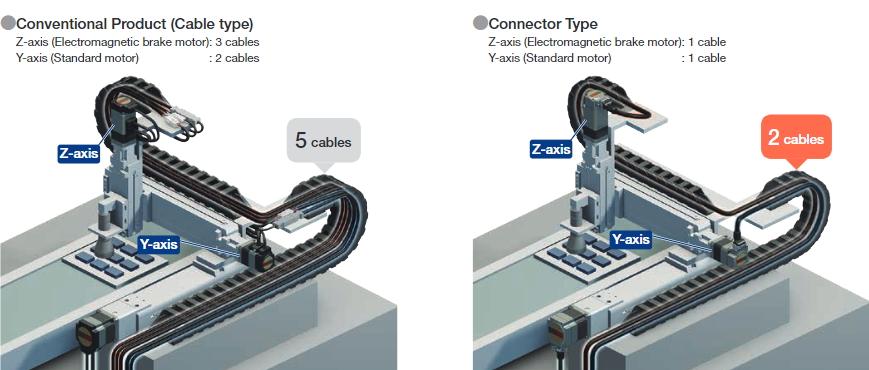

By consolidating all the cables into one, only one cable is needed per motor. For instance, in the example below, five cables for the Y and Z axes in a Cartesian system are reduced to two cables. This results in a smaller cable holder.

---

**

**

---

**Background**

Oriental Motor’s customer-facing teams regularly seek feedback to improve our products. In this case, several customers provided feedback about our AZ Series cable type motors, which are our popular closed-loop motors and drivers featuring AlphaStep hybrid open/closed-loop control technology and a patented built-in mechanical absolute encoder.

- A customer was using an AZ Series cable type motor in a test process to address homing accuracy issues caused by thermal expansion of an external photo sensor. To simplify cable routing, they suggested consolidating the cables between the motors and drivers.

- Another customer was using a 20 mm frame size AZ Series cable type motor to position a stage in a tight space and was using joining cables to extend the cable from the motor to the driver. However, the joining connectors were too large to fit, and they also had concerns about electrical noise interference and washdown risks due to the exposed connectors on the joining cables. To solve these problems, they recommended eliminating the middle extension cable.

- A third customer was using an AZ Series cable type motor for an LED equipment and needed flexible cables for routing around internal components. In the cable type motor, there's a part of the cable that’s not flexible, and they suggested making the entire cable flexible.

In response to this valuable feedback, Oriental Motor has launched a **new line of AZ Series connector type motors** using a new **flat connector** from Hirose Electric to enhance usability and a **consolidated cable** to make it easier to connect to the drivers.

In the **standard cable type motor**, the motor typically has multiple pigtail cables, including those for the motor, encoder, protective earth ground, and electromagnetic brake (for brake motor types). To connect to the driver, a middle extension cable is necessary.

In the **new connector type motor**, we’ve enhanced the design of the connector and combined all the cables into one cable, making these motors easier to use, simpler to maintain, and better suited for tighter spaces.

Let’s take a closer look and explore the advantages the new connector type motors can offer.

---

**Benefits of One Cable Technology**

**Unification of Cables**

- Reduce routing work and downsize cable holders.

By consolidating all the cables into one, only one cable is needed per motor. For instance, in the example below, five cables for the Y and Z axes in a Cartesian system are reduced to two cables. This results in a smaller cable holder.

---

** **

---

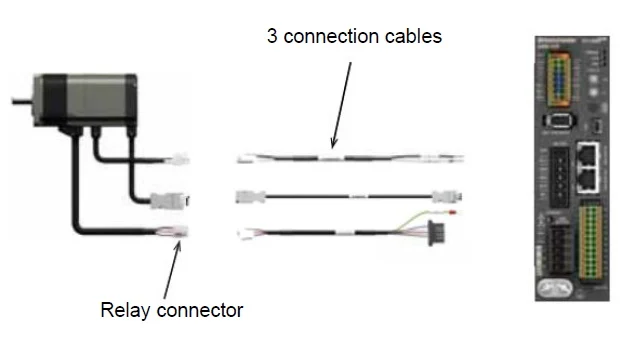

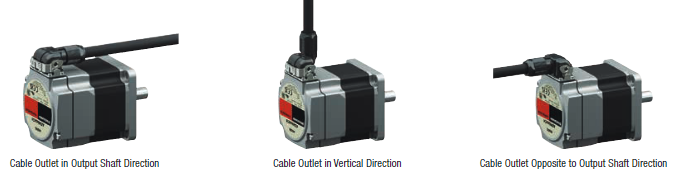

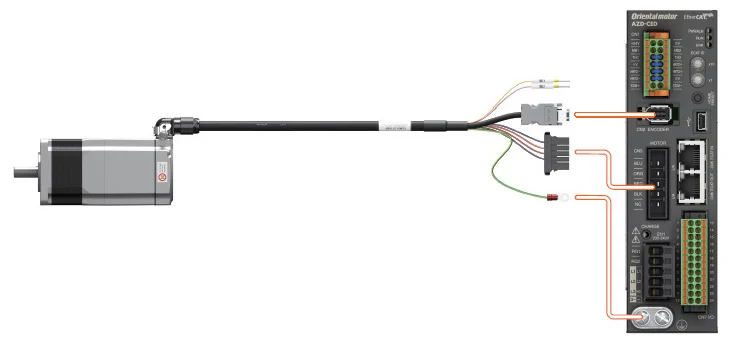

**Direct Connection**

- No more middle joining cables.

For the cable type motor, a connection cable is required to extend the cable beyond the standard pigtail length of 300 mm. Sometimes, electrical noise emanates from the exposed connectors between the cables, affecting other machine components. The new connector type motor uses one cable technology, reducing electrical noise interference (EMI).

---

**

**

---

**Direct Connection**

- No more middle joining cables.

For the cable type motor, a connection cable is required to extend the cable beyond the standard pigtail length of 300 mm. Sometimes, electrical noise emanates from the exposed connectors between the cables, affecting other machine components. The new connector type motor uses one cable technology, reducing electrical noise interference (EMI).

---

** **

---

**

**

---

** **

---

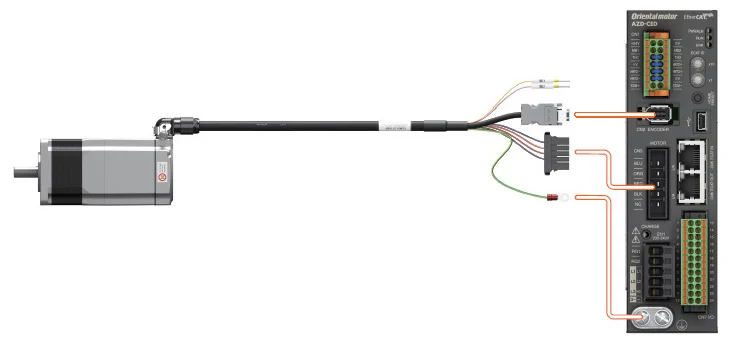

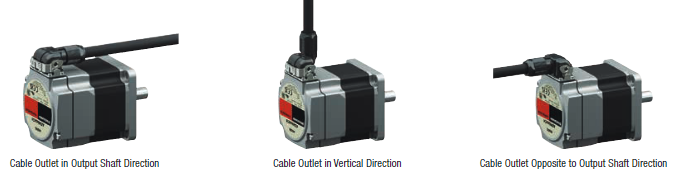

**3 Cable Outlet Directions for Flexibility**

- Select from three cable outlet directions.

The connector and cable come in three configurations: shaft direction, vertical direction, or opposite to the output shaft direction. You must order the connection cable this way (use "F" = front, "B" = back, "V" = vertical in the cable part number). This increases the degree of cable outlet freedom around the motor.

---

**

**

---

**3 Cable Outlet Directions for Flexibility**

- Select from three cable outlet directions.

The connector and cable come in three configurations: shaft direction, vertical direction, or opposite to the output shaft direction. You must order the connection cable this way (use "F" = front, "B" = back, "V" = vertical in the cable part number). This increases the degree of cable outlet freedom around the motor.

---

** **

---

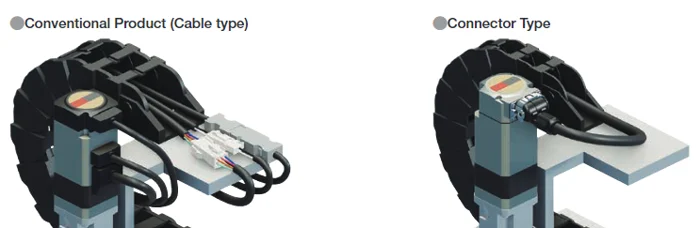

**Faster Maintenance**

- Direct connection leads to quicker replacement of motors and cables.

Perform swift motor maintenance by dealing with fewer cables (and downsizing your cable tracks). Below is an example of the difference.

---

**

**

---

**Faster Maintenance**

- Direct connection leads to quicker replacement of motors and cables.

Perform swift motor maintenance by dealing with fewer cables (and downsizing your cable tracks). Below is an example of the difference.

---

** **

---

**Reduced Material**

- By consolidating the cable, the materials used to manufacture the cables are reduced.

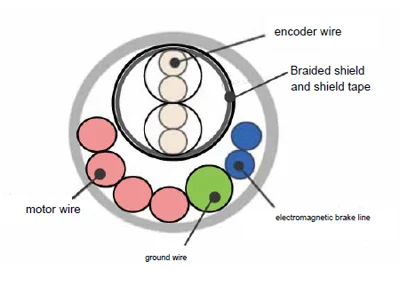

Electrical cables consist of a conductive metal wire core (such as copper or aluminum), surrounded by various layers of materials like insulation, tapes, screens, armor for mechanical protection, and sheathing. By consolidating three cables into one, we reduced the cross-sectional area by 44.3% and the mass by 55.5%.

---

**

**

---

**Reduced Material**

- By consolidating the cable, the materials used to manufacture the cables are reduced.

Electrical cables consist of a conductive metal wire core (such as copper or aluminum), surrounded by various layers of materials like insulation, tapes, screens, armor for mechanical protection, and sheathing. By consolidating three cables into one, we reduced the cross-sectional area by 44.3% and the mass by 55.5%.

---

** **

---

**Easy Installation**

- Lock lever connector for simple connection.

Connecting the cable is straightforward thanks to the lock lever, which doesn’t require screws. Simply insert the connector and lock the lever.

---

**

**

---

**Easy Installation**

- Lock lever connector for simple connection.

Connecting the cable is straightforward thanks to the lock lever, which doesn’t require screws. Simply insert the connector and lock the lever.

---

** **

---

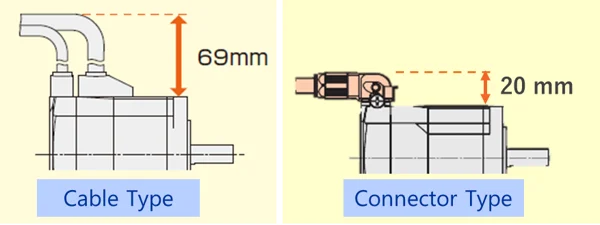

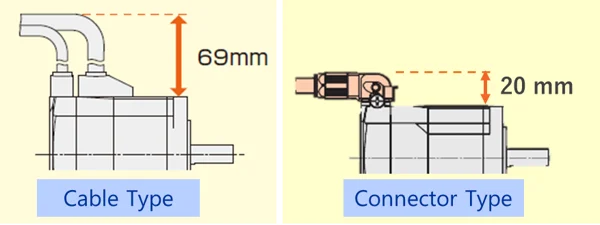

**Low Profile, Flat Connector**

- A motor with a flat connector can fit into tighter spaces.

The new low-profile flat connector is 49 mm shorter in height compared to the cable type.

---

**

**

---

**Low Profile, Flat Connector**

- A motor with a flat connector can fit into tighter spaces.

The new low-profile flat connector is 49 mm shorter in height compared to the cable type.

---

** **

---

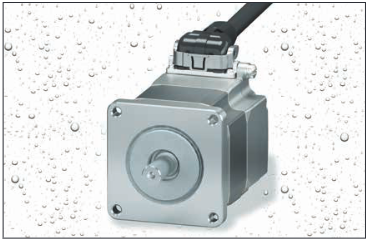

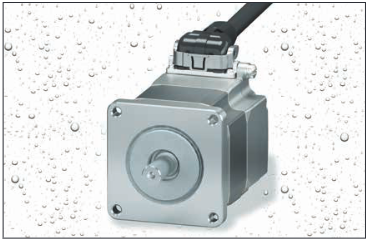

**Maintains High Ingress Protection**

- The new connector and cable maintain an IP66 ingress protection rating for dusty or washdown environments.

Same as the cable type motor, the connector type motors maintain the IP66 rating, meaning they can handle a sprayed water jet of 100 kPa at a rate of 100 l/min for 3 minutes from all directions at a distance of 3 meters.

---

**

**

---

**Maintains High Ingress Protection**

- The new connector and cable maintain an IP66 ingress protection rating for dusty or washdown environments.

Same as the cable type motor, the connector type motors maintain the IP66 rating, meaning they can handle a sprayed water jet of 100 kPa at a rate of 100 l/min for 3 minutes from all directions at a distance of 3 meters.

---

** **

---

**âš¡ One Cable Challenge: Dealing with Electrical Noise**

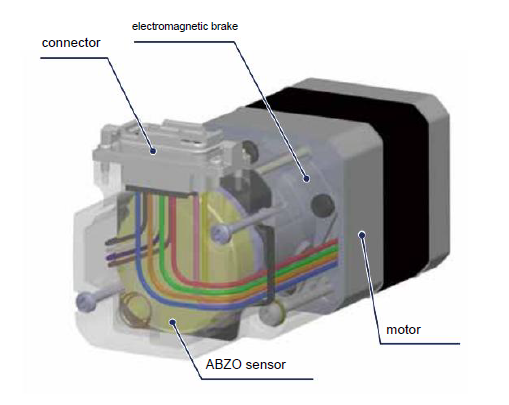

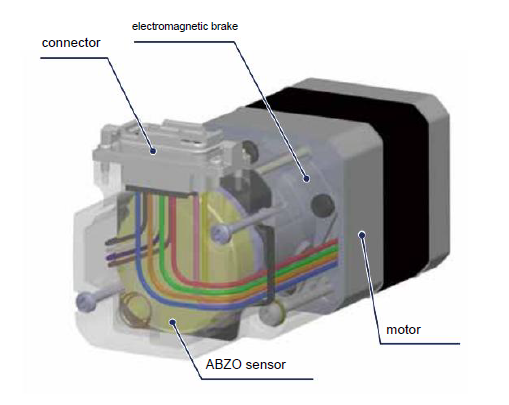

Stepper motors are driven by PWM (Pulse Width Modulation) control, so radiated noise is generated from the motor signals as it switches phases during rotation. Due to this issue, conventional cables had to separate the low-signal encoder cable and the electromagnetic brake cable from the motor cable.

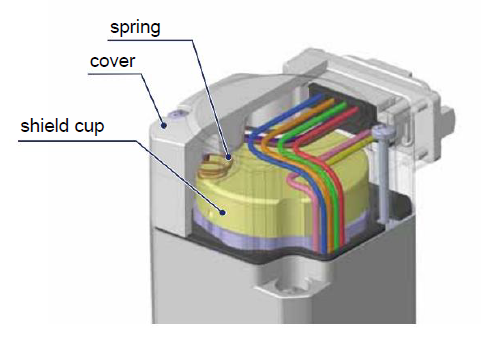

To combine all signals into one cable and prevent issues from electrical noise or magnetic interference inside the motor, we needed to redesign the motor internally and reroute the motor and electromagnetic brake wires inside the motor.

---

**

**

---

**âš¡ One Cable Challenge: Dealing with Electrical Noise**

Stepper motors are driven by PWM (Pulse Width Modulation) control, so radiated noise is generated from the motor signals as it switches phases during rotation. Due to this issue, conventional cables had to separate the low-signal encoder cable and the electromagnetic brake cable from the motor cable.

To combine all signals into one cable and prevent issues from electrical noise or magnetic interference inside the motor, we needed to redesign the motor internally and reroute the motor and electromagnetic brake wires inside the motor.

---

** **

---

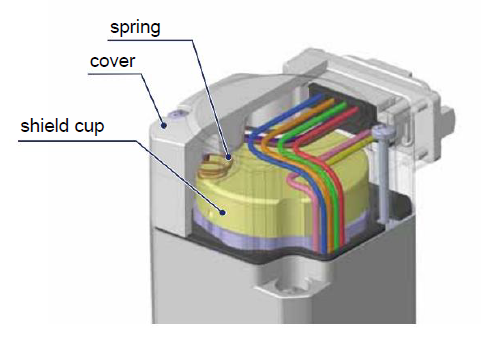

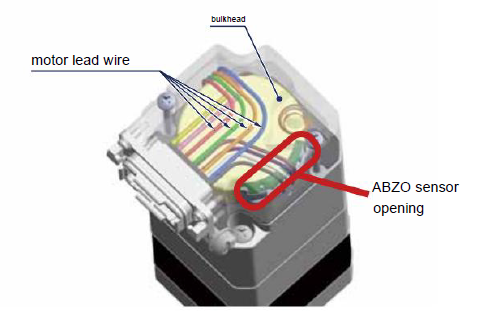

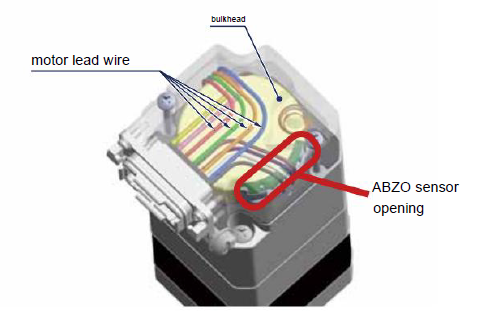

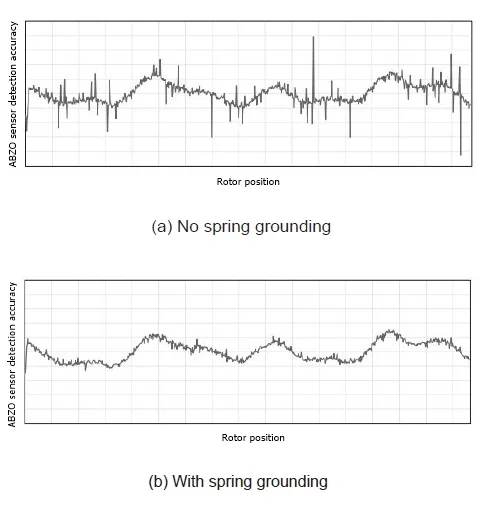

The built-in mechanical absolute encoder has a steel shield cup covering it since it's a type of magnetic sensor that uses a series of permanent magnets to track absolute position coordinates like clocks. To prevent the effects of external magnetic fields, the magnetic sensor is housed inside a steel shield cup. To protect against electrical noise interference, the shield cup and motor casing are now electrically grounded using a metal spring. The magnetic sensor opening has also been sealed.

---

**

**

---

The built-in mechanical absolute encoder has a steel shield cup covering it since it's a type of magnetic sensor that uses a series of permanent magnets to track absolute position coordinates like clocks. To prevent the effects of external magnetic fields, the magnetic sensor is housed inside a steel shield cup. To protect against electrical noise interference, the shield cup and motor casing are now electrically grounded using a metal spring. The magnetic sensor opening has also been sealed.

---

** **

---

**

**

---

** **

---

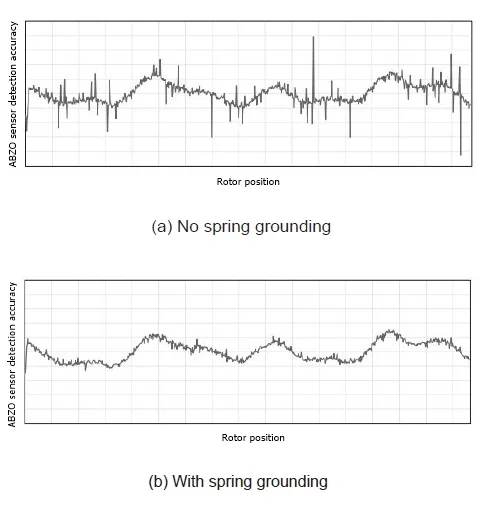

By forcing an electrical ground using a metal spring, noise propagation to the ABZO sensor is eliminated by setting the shield cup and motor housing to the same potential and providing a way to absorb radiation noise.

---

**

**

---

By forcing an electrical ground using a metal spring, noise propagation to the ABZO sensor is eliminated by setting the shield cup and motor housing to the same potential and providing a way to absorb radiation noise.

---

** **

---

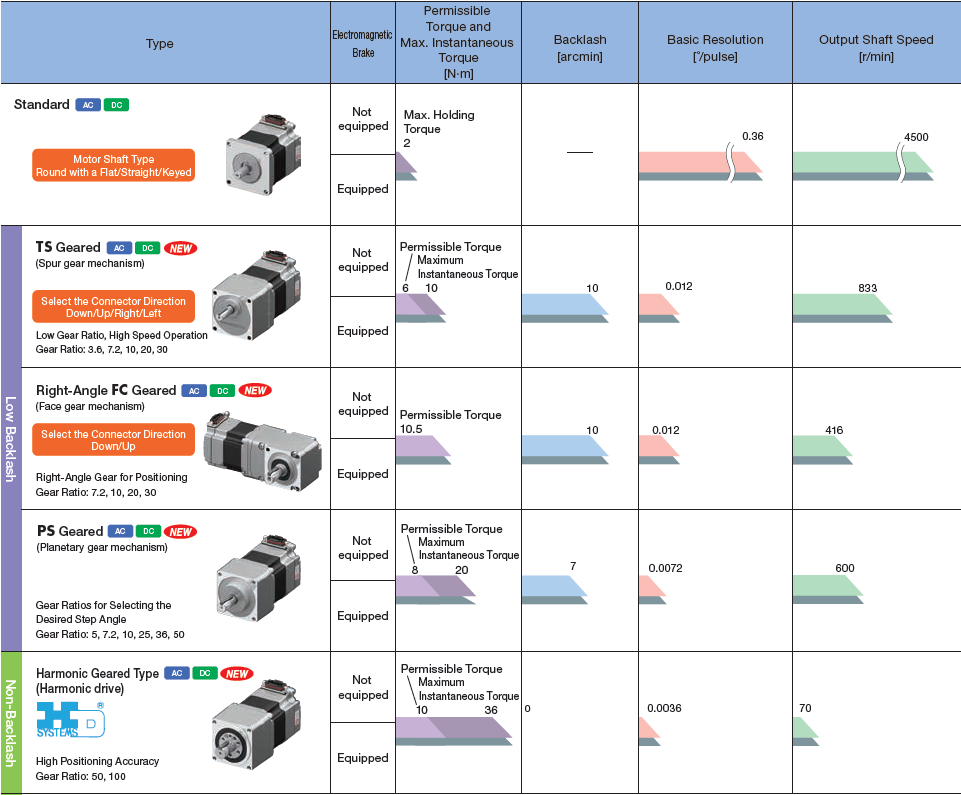

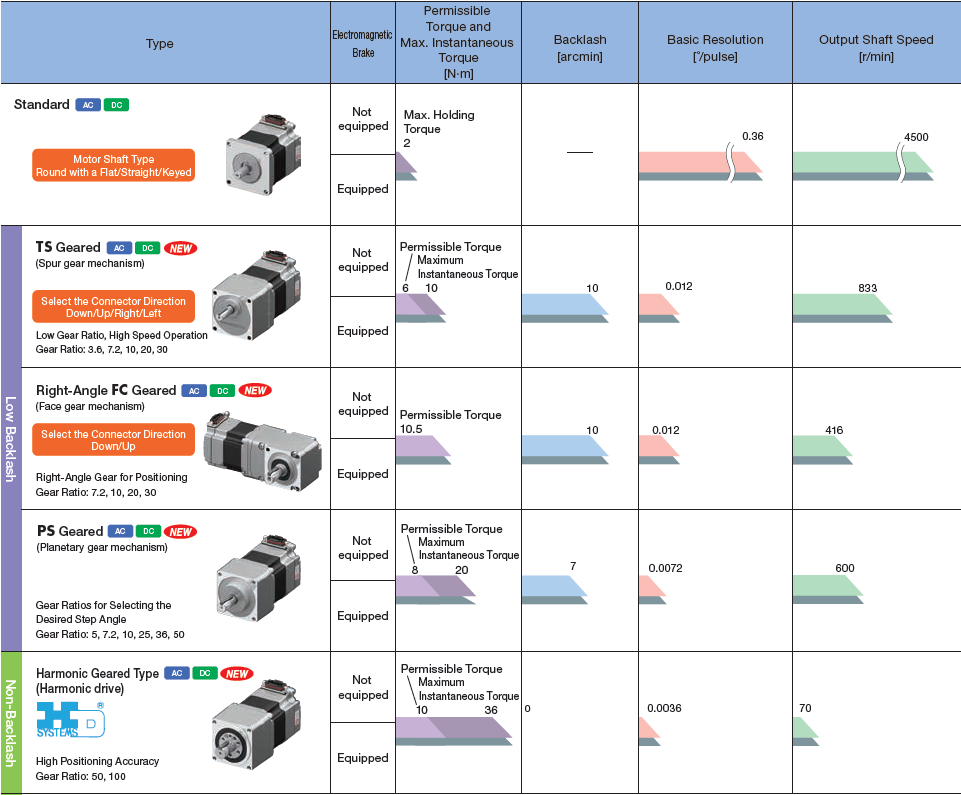

**Product Lineup**

The AlphaStep AZ Series connector type motors are available in two frame sizes: 42 mm and 60 mm. More frame sizes will become available as we expand this series over time. The specifications and flange size are the same as the traditional cable type, so it's easy to upgrade AZ Series cable type motors to connector type motors without missing a beat.

The connector type motor can be ordered with various preassembled gearhead options, such as the TS spur gear, right-angle FC "face" gear, PS planetary gear, or harmonic gear. In the future, we also plan to expand the connector type motor to linear and rotary actuators.

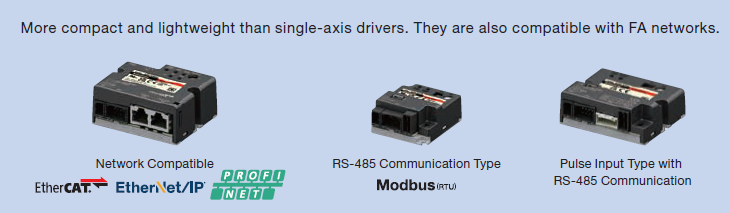

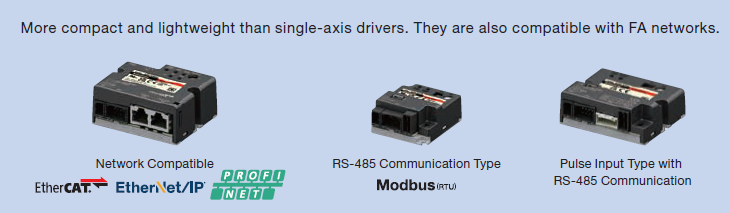

The connector type motor is compatible with all drivers from the AZ Series: AC input, DC input, and mini drivers. Common industrial communication protocols include EtherNet/IP, EtherCAT, Profinet, and other popular networks.

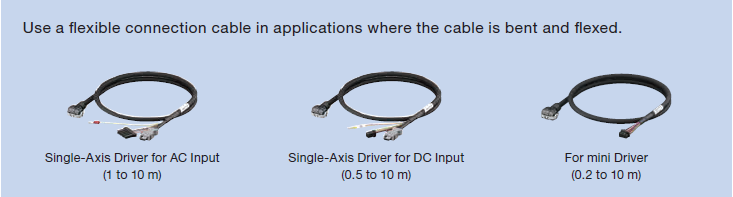

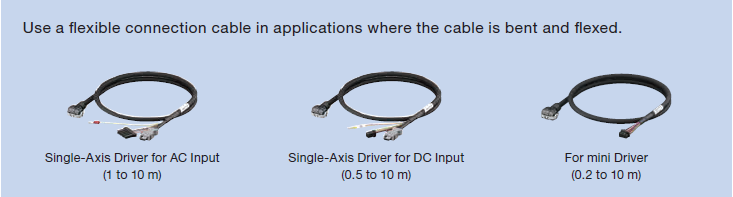

Cable lengths for the connector type motors range from 1 to 10 meters for AC input drivers; 0.5 to 10 meters for DC input, and 0.2 to 10 meters for mini drivers.

---

**

**

---

**Product Lineup**

The AlphaStep AZ Series connector type motors are available in two frame sizes: 42 mm and 60 mm. More frame sizes will become available as we expand this series over time. The specifications and flange size are the same as the traditional cable type, so it's easy to upgrade AZ Series cable type motors to connector type motors without missing a beat.

The connector type motor can be ordered with various preassembled gearhead options, such as the TS spur gear, right-angle FC "face" gear, PS planetary gear, or harmonic gear. In the future, we also plan to expand the connector type motor to linear and rotary actuators.

The connector type motor is compatible with all drivers from the AZ Series: AC input, DC input, and mini drivers. Common industrial communication protocols include EtherNet/IP, EtherCAT, Profinet, and other popular networks.

Cable lengths for the connector type motors range from 1 to 10 meters for AC input drivers; 0.5 to 10 meters for DC input, and 0.2 to 10 meters for mini drivers.

---

** **

---

The new AZ Series connector type motors are also compatible with our mini drivers. These are our smallest closed-loop drivers.

---

**

**

---

The new AZ Series connector type motors are also compatible with our mini drivers. These are our smallest closed-loop drivers.

---

** **

---

Choose the right connection cable or flexible connection cable for your AC input, DC input, or mini driver. One cable locking connector allows for a maximum of 10 meters (32.8 feet) between the motor and driver, with the same motor performance specifications as our standard cable-type AZ Series. Current motor cable connections are not compatible with multi-axis drivers.

---

**

**

---

Choose the right connection cable or flexible connection cable for your AC input, DC input, or mini driver. One cable locking connector allows for a maximum of 10 meters (32.8 feet) between the motor and driver, with the same motor performance specifications as our standard cable-type AZ Series. Current motor cable connections are not compatible with multi-axis drivers.

---

** **

---

**Summary**

In summary, a consolidated cable offers these eight benefits:

- Fewer cables to manage.

- Direct connection from motor to driver without a middle extension cable.

- Three cable outlet directions to choose from.

- Reduced maintenance with fewer cables to route.

- A consolidated cable helps reduce material usage.

- One cable makes installation easier and faster.

- A low-profile, flat connector for a smaller motor footprint.

- Maintains IP66 ingress protection rating.

Until wireless motion control becomes feasible, cables will remain essential to any motion control system, whether it involves motors, linear actuators, or rotary actuators. By consolidating the motor cables for the AZ Series connector type, Oriental Motor aims to make motor installation and maintenance easier and faster for all engineers involved.

---

**Update: March 18th, 2024**

There’s **one more reason to upgrade** to the AZ Series connector type motors.

Released in 2024, these “integrated motor†style driver mounting brackets can be used to mount an AZ Series mini driver to a connector type motor, saving space and simplifying cabling.

These mounting brackets are currently available for 42 mm and 60 mm frame size connector type motors.

---

**

**

---

**Summary**

In summary, a consolidated cable offers these eight benefits:

- Fewer cables to manage.

- Direct connection from motor to driver without a middle extension cable.

- Three cable outlet directions to choose from.

- Reduced maintenance with fewer cables to route.

- A consolidated cable helps reduce material usage.

- One cable makes installation easier and faster.

- A low-profile, flat connector for a smaller motor footprint.

- Maintains IP66 ingress protection rating.

Until wireless motion control becomes feasible, cables will remain essential to any motion control system, whether it involves motors, linear actuators, or rotary actuators. By consolidating the motor cables for the AZ Series connector type, Oriental Motor aims to make motor installation and maintenance easier and faster for all engineers involved.

---

**Update: March 18th, 2024**

There’s **one more reason to upgrade** to the AZ Series connector type motors.

Released in 2024, these “integrated motor†style driver mounting brackets can be used to mount an AZ Series mini driver to a connector type motor, saving space and simplifying cabling.

These mounting brackets are currently available for 42 mm and 60 mm frame size connector type motors.

---

** **

---

Is there a product feature you’d like to see in our products? Let us know!

---

This version maintains the original intent while adding more depth and detail, ensuring it surpasses the 500-character threshold naturally.

**

---

Is there a product feature you’d like to see in our products? Let us know!

---

This version maintains the original intent while adding more depth and detail, ensuring it surpasses the 500-character threshold naturally.

**

---

**Background**

Oriental Motor’s customer-facing teams regularly seek feedback to improve our products. In this case, several customers provided feedback about our AZ Series cable type motors, which are our popular closed-loop motors and drivers featuring AlphaStep hybrid open/closed-loop control technology and a patented built-in mechanical absolute encoder.

- A customer was using an AZ Series cable type motor in a test process to address homing accuracy issues caused by thermal expansion of an external photo sensor. To simplify cable routing, they suggested consolidating the cables between the motors and drivers.

- Another customer was using a 20 mm frame size AZ Series cable type motor to position a stage in a tight space and was using joining cables to extend the cable from the motor to the driver. However, the joining connectors were too large to fit, and they also had concerns about electrical noise interference and washdown risks due to the exposed connectors on the joining cables. To solve these problems, they recommended eliminating the middle extension cable.

- A third customer was using an AZ Series cable type motor for an LED equipment and needed flexible cables for routing around internal components. In the cable type motor, there's a part of the cable that’s not flexible, and they suggested making the entire cable flexible.

In response to this valuable feedback, Oriental Motor has launched a **new line of AZ Series connector type motors** using a new **flat connector** from Hirose Electric to enhance usability and a **consolidated cable** to make it easier to connect to the drivers.

In the **standard cable type motor**, the motor typically has multiple pigtail cables, including those for the motor, encoder, protective earth ground, and electromagnetic brake (for brake motor types). To connect to the driver, a middle extension cable is necessary.

In the **new connector type motor**, we’ve enhanced the design of the connector and combined all the cables into one cable, making these motors easier to use, simpler to maintain, and better suited for tighter spaces.

Let’s take a closer look and explore the advantages the new connector type motors can offer.

---

**Benefits of One Cable Technology**

**Unification of Cables**

- Reduce routing work and downsize cable holders.

By consolidating all the cables into one, only one cable is needed per motor. For instance, in the example below, five cables for the Y and Z axes in a Cartesian system are reduced to two cables. This results in a smaller cable holder.

---

**

**

---

**Background**

Oriental Motor’s customer-facing teams regularly seek feedback to improve our products. In this case, several customers provided feedback about our AZ Series cable type motors, which are our popular closed-loop motors and drivers featuring AlphaStep hybrid open/closed-loop control technology and a patented built-in mechanical absolute encoder.

- A customer was using an AZ Series cable type motor in a test process to address homing accuracy issues caused by thermal expansion of an external photo sensor. To simplify cable routing, they suggested consolidating the cables between the motors and drivers.

- Another customer was using a 20 mm frame size AZ Series cable type motor to position a stage in a tight space and was using joining cables to extend the cable from the motor to the driver. However, the joining connectors were too large to fit, and they also had concerns about electrical noise interference and washdown risks due to the exposed connectors on the joining cables. To solve these problems, they recommended eliminating the middle extension cable.

- A third customer was using an AZ Series cable type motor for an LED equipment and needed flexible cables for routing around internal components. In the cable type motor, there's a part of the cable that’s not flexible, and they suggested making the entire cable flexible.

In response to this valuable feedback, Oriental Motor has launched a **new line of AZ Series connector type motors** using a new **flat connector** from Hirose Electric to enhance usability and a **consolidated cable** to make it easier to connect to the drivers.

In the **standard cable type motor**, the motor typically has multiple pigtail cables, including those for the motor, encoder, protective earth ground, and electromagnetic brake (for brake motor types). To connect to the driver, a middle extension cable is necessary.

In the **new connector type motor**, we’ve enhanced the design of the connector and combined all the cables into one cable, making these motors easier to use, simpler to maintain, and better suited for tighter spaces.

Let’s take a closer look and explore the advantages the new connector type motors can offer.

---

**Benefits of One Cable Technology**

**Unification of Cables**

- Reduce routing work and downsize cable holders.

By consolidating all the cables into one, only one cable is needed per motor. For instance, in the example below, five cables for the Y and Z axes in a Cartesian system are reduced to two cables. This results in a smaller cable holder.

---

** **

---

**Direct Connection**

- No more middle joining cables.

For the cable type motor, a connection cable is required to extend the cable beyond the standard pigtail length of 300 mm. Sometimes, electrical noise emanates from the exposed connectors between the cables, affecting other machine components. The new connector type motor uses one cable technology, reducing electrical noise interference (EMI).

---

**

**

---

**Direct Connection**

- No more middle joining cables.

For the cable type motor, a connection cable is required to extend the cable beyond the standard pigtail length of 300 mm. Sometimes, electrical noise emanates from the exposed connectors between the cables, affecting other machine components. The new connector type motor uses one cable technology, reducing electrical noise interference (EMI).

---

** **

---

**

**

---

** **

---

**3 Cable Outlet Directions for Flexibility**

- Select from three cable outlet directions.

The connector and cable come in three configurations: shaft direction, vertical direction, or opposite to the output shaft direction. You must order the connection cable this way (use "F" = front, "B" = back, "V" = vertical in the cable part number). This increases the degree of cable outlet freedom around the motor.

---

**

**

---

**3 Cable Outlet Directions for Flexibility**

- Select from three cable outlet directions.

The connector and cable come in three configurations: shaft direction, vertical direction, or opposite to the output shaft direction. You must order the connection cable this way (use "F" = front, "B" = back, "V" = vertical in the cable part number). This increases the degree of cable outlet freedom around the motor.

---

** **

---

**Faster Maintenance**

- Direct connection leads to quicker replacement of motors and cables.

Perform swift motor maintenance by dealing with fewer cables (and downsizing your cable tracks). Below is an example of the difference.

---

**

**

---

**Faster Maintenance**

- Direct connection leads to quicker replacement of motors and cables.

Perform swift motor maintenance by dealing with fewer cables (and downsizing your cable tracks). Below is an example of the difference.

---

** **

---

**Reduced Material**

- By consolidating the cable, the materials used to manufacture the cables are reduced.

Electrical cables consist of a conductive metal wire core (such as copper or aluminum), surrounded by various layers of materials like insulation, tapes, screens, armor for mechanical protection, and sheathing. By consolidating three cables into one, we reduced the cross-sectional area by 44.3% and the mass by 55.5%.

---

**

**

---

**Reduced Material**

- By consolidating the cable, the materials used to manufacture the cables are reduced.

Electrical cables consist of a conductive metal wire core (such as copper or aluminum), surrounded by various layers of materials like insulation, tapes, screens, armor for mechanical protection, and sheathing. By consolidating three cables into one, we reduced the cross-sectional area by 44.3% and the mass by 55.5%.

---

** **

---

**Easy Installation**

- Lock lever connector for simple connection.

Connecting the cable is straightforward thanks to the lock lever, which doesn’t require screws. Simply insert the connector and lock the lever.

---

**

**

---

**Easy Installation**

- Lock lever connector for simple connection.

Connecting the cable is straightforward thanks to the lock lever, which doesn’t require screws. Simply insert the connector and lock the lever.

---

** **

---

**Low Profile, Flat Connector**

- A motor with a flat connector can fit into tighter spaces.

The new low-profile flat connector is 49 mm shorter in height compared to the cable type.

---

**

**

---

**Low Profile, Flat Connector**

- A motor with a flat connector can fit into tighter spaces.

The new low-profile flat connector is 49 mm shorter in height compared to the cable type.

---

** **

---

**Maintains High Ingress Protection**

- The new connector and cable maintain an IP66 ingress protection rating for dusty or washdown environments.

Same as the cable type motor, the connector type motors maintain the IP66 rating, meaning they can handle a sprayed water jet of 100 kPa at a rate of 100 l/min for 3 minutes from all directions at a distance of 3 meters.

---

**

**

---

**Maintains High Ingress Protection**

- The new connector and cable maintain an IP66 ingress protection rating for dusty or washdown environments.

Same as the cable type motor, the connector type motors maintain the IP66 rating, meaning they can handle a sprayed water jet of 100 kPa at a rate of 100 l/min for 3 minutes from all directions at a distance of 3 meters.

---

** **

---

**âš¡ One Cable Challenge: Dealing with Electrical Noise**

Stepper motors are driven by PWM (Pulse Width Modulation) control, so radiated noise is generated from the motor signals as it switches phases during rotation. Due to this issue, conventional cables had to separate the low-signal encoder cable and the electromagnetic brake cable from the motor cable.

To combine all signals into one cable and prevent issues from electrical noise or magnetic interference inside the motor, we needed to redesign the motor internally and reroute the motor and electromagnetic brake wires inside the motor.

---

**

**

---

**âš¡ One Cable Challenge: Dealing with Electrical Noise**

Stepper motors are driven by PWM (Pulse Width Modulation) control, so radiated noise is generated from the motor signals as it switches phases during rotation. Due to this issue, conventional cables had to separate the low-signal encoder cable and the electromagnetic brake cable from the motor cable.

To combine all signals into one cable and prevent issues from electrical noise or magnetic interference inside the motor, we needed to redesign the motor internally and reroute the motor and electromagnetic brake wires inside the motor.

---

** **

---

The built-in mechanical absolute encoder has a steel shield cup covering it since it's a type of magnetic sensor that uses a series of permanent magnets to track absolute position coordinates like clocks. To prevent the effects of external magnetic fields, the magnetic sensor is housed inside a steel shield cup. To protect against electrical noise interference, the shield cup and motor casing are now electrically grounded using a metal spring. The magnetic sensor opening has also been sealed.

---

**

**

---

The built-in mechanical absolute encoder has a steel shield cup covering it since it's a type of magnetic sensor that uses a series of permanent magnets to track absolute position coordinates like clocks. To prevent the effects of external magnetic fields, the magnetic sensor is housed inside a steel shield cup. To protect against electrical noise interference, the shield cup and motor casing are now electrically grounded using a metal spring. The magnetic sensor opening has also been sealed.

---

** **

---

**

**

---

** **

---

By forcing an electrical ground using a metal spring, noise propagation to the ABZO sensor is eliminated by setting the shield cup and motor housing to the same potential and providing a way to absorb radiation noise.

---

**

**

---

By forcing an electrical ground using a metal spring, noise propagation to the ABZO sensor is eliminated by setting the shield cup and motor housing to the same potential and providing a way to absorb radiation noise.

---

** **

---

**Product Lineup**

The AlphaStep AZ Series connector type motors are available in two frame sizes: 42 mm and 60 mm. More frame sizes will become available as we expand this series over time. The specifications and flange size are the same as the traditional cable type, so it's easy to upgrade AZ Series cable type motors to connector type motors without missing a beat.

The connector type motor can be ordered with various preassembled gearhead options, such as the TS spur gear, right-angle FC "face" gear, PS planetary gear, or harmonic gear. In the future, we also plan to expand the connector type motor to linear and rotary actuators.

The connector type motor is compatible with all drivers from the AZ Series: AC input, DC input, and mini drivers. Common industrial communication protocols include EtherNet/IP, EtherCAT, Profinet, and other popular networks.

Cable lengths for the connector type motors range from 1 to 10 meters for AC input drivers; 0.5 to 10 meters for DC input, and 0.2 to 10 meters for mini drivers.

---

**

**

---

**Product Lineup**

The AlphaStep AZ Series connector type motors are available in two frame sizes: 42 mm and 60 mm. More frame sizes will become available as we expand this series over time. The specifications and flange size are the same as the traditional cable type, so it's easy to upgrade AZ Series cable type motors to connector type motors without missing a beat.

The connector type motor can be ordered with various preassembled gearhead options, such as the TS spur gear, right-angle FC "face" gear, PS planetary gear, or harmonic gear. In the future, we also plan to expand the connector type motor to linear and rotary actuators.

The connector type motor is compatible with all drivers from the AZ Series: AC input, DC input, and mini drivers. Common industrial communication protocols include EtherNet/IP, EtherCAT, Profinet, and other popular networks.

Cable lengths for the connector type motors range from 1 to 10 meters for AC input drivers; 0.5 to 10 meters for DC input, and 0.2 to 10 meters for mini drivers.

---

** **

---

The new AZ Series connector type motors are also compatible with our mini drivers. These are our smallest closed-loop drivers.

---

**

**

---

The new AZ Series connector type motors are also compatible with our mini drivers. These are our smallest closed-loop drivers.

---

** **

---

Choose the right connection cable or flexible connection cable for your AC input, DC input, or mini driver. One cable locking connector allows for a maximum of 10 meters (32.8 feet) between the motor and driver, with the same motor performance specifications as our standard cable-type AZ Series. Current motor cable connections are not compatible with multi-axis drivers.

---

**

**

---

Choose the right connection cable or flexible connection cable for your AC input, DC input, or mini driver. One cable locking connector allows for a maximum of 10 meters (32.8 feet) between the motor and driver, with the same motor performance specifications as our standard cable-type AZ Series. Current motor cable connections are not compatible with multi-axis drivers.

---

** **

---

**Summary**

In summary, a consolidated cable offers these eight benefits:

- Fewer cables to manage.

- Direct connection from motor to driver without a middle extension cable.

- Three cable outlet directions to choose from.

- Reduced maintenance with fewer cables to route.

- A consolidated cable helps reduce material usage.

- One cable makes installation easier and faster.

- A low-profile, flat connector for a smaller motor footprint.

- Maintains IP66 ingress protection rating.

Until wireless motion control becomes feasible, cables will remain essential to any motion control system, whether it involves motors, linear actuators, or rotary actuators. By consolidating the motor cables for the AZ Series connector type, Oriental Motor aims to make motor installation and maintenance easier and faster for all engineers involved.

---

**Update: March 18th, 2024**

There’s **one more reason to upgrade** to the AZ Series connector type motors.

Released in 2024, these “integrated motor†style driver mounting brackets can be used to mount an AZ Series mini driver to a connector type motor, saving space and simplifying cabling.

These mounting brackets are currently available for 42 mm and 60 mm frame size connector type motors.

---

**

**

---

**Summary**

In summary, a consolidated cable offers these eight benefits:

- Fewer cables to manage.

- Direct connection from motor to driver without a middle extension cable.

- Three cable outlet directions to choose from.

- Reduced maintenance with fewer cables to route.

- A consolidated cable helps reduce material usage.

- One cable makes installation easier and faster.

- A low-profile, flat connector for a smaller motor footprint.

- Maintains IP66 ingress protection rating.

Until wireless motion control becomes feasible, cables will remain essential to any motion control system, whether it involves motors, linear actuators, or rotary actuators. By consolidating the motor cables for the AZ Series connector type, Oriental Motor aims to make motor installation and maintenance easier and faster for all engineers involved.

---

**Update: March 18th, 2024**

There’s **one more reason to upgrade** to the AZ Series connector type motors.

Released in 2024, these “integrated motor†style driver mounting brackets can be used to mount an AZ Series mini driver to a connector type motor, saving space and simplifying cabling.

These mounting brackets are currently available for 42 mm and 60 mm frame size connector type motors.

---

** **

---

Is there a product feature you’d like to see in our products? Let us know!

---

This version maintains the original intent while adding more depth and detail, ensuring it surpasses the 500-character threshold naturally.

**

---

Is there a product feature you’d like to see in our products? Let us know!

---

This version maintains the original intent while adding more depth and detail, ensuring it surpasses the 500-character threshold naturally.All the Electronic Jacquard Controller under this classification are applicable to all series of electronic jacquard machines..SJC9 Series controllers have several features include private data storage is easy to be preserved, strong anti-interference ability of industrial dedicated single chip, tiny body with options of installation and simple and easy for use.

Electronic Jacquard Controller, Jacquard loom Controller,Jacquard Machine Controller,Electronic Jacquard Control Panel

JIANGSU S&S INTELLIGENT SCIENCE AND TECHNOLOGY CO., LTD , https://www.ssjacquard.com