US Commerce Secretary Ross announced on the 17th that he initiated anti-dumping and countervailing investigations on steel wheel products produced in China (ie, "double-reverse" investigation). On the same day, the US Department of Commerce also initially imposed a subsidy on the general aluminum alloy plates imported from China.

In a statement about China's steel wheel products, Ross said that the US Department of Commerce will act quickly and conduct a comprehensive and fair assessment of relevant facts to ensure that American companies and workers have equal opportunities to compete.

The US Department of Commerce said that the launch of the "double-reverse" investigation was in response to a complaint filed by two US companies on March 27. It is estimated that the above products have a dumping margin of 12.1% to 231.7% and involve 56 subsidy programs.

According to the US trade remedy procedure, another US agency, the US International Trade Commission, will cut the steel wheel products imported from China before May 11 to cause substantial damage to the relevant industries in the United States. If the committee makes a positive preliminary ruling, the Ministry of Commerce will continue the "double-reverse" investigation, and plans to make countervailing and anti-dumping preliminary rulings on June 20 and September 4, respectively.

According to data from the US Department of Commerce, the amount of steel wheel products imported from China in 2017 was approximately $388 million.

On the same day, Ross also said in another statement that the US Department of Commerce’s preliminary ruling found that there were subsidies for the general-purpose aluminum alloy plates imported from China, with a subsidy range of 31.2% to 113.3%.

On November 28 last year, the US Department of Commerce issued an announcement to independently launch a “double-reverse†investigation on the general-purpose aluminum alloy plates imported from China. This is the first time that the US Department of Commerce has not applied for domestic industry applications for 25 years, but has independently initiated trade remedies. survey.

In view of the preliminary results on the 17th, the US Department of Commerce will notify the US Customs to impose a corresponding deposit on the general-purpose aluminum alloy plates imported from China. The US Department of Commerce plans to make a final ruling on the countervailing investigation against the above products on August 30. If the US International Trade Commission also makes a positive final ruling on October 15, the United States will formally impose countervailing duties on the above products. .

The Chinese Ministry of Commerce has repeatedly stated that it hopes that the US government will abide by its commitment to oppose trade protectionism, jointly safeguard a free, open and fair international trade environment, and properly handle trade frictions in a more rational way.

Melt-blown fabrics have generally the same applications as other nonwoven products. The main uses of melt-blown nonwovens and other innovative approaches are as follows.

300mm Meltblown Spinneret for Meltblown Medical Mask Nonwoven Fabric Producing

Melt-blown spinning is to blow a molten polymer through a high-temperature high-speed gas to refine the polymer into a filament to form a nonwoven fabric.

1. Stainless steel wear resistant and corrosion resistant.

2. Hole number encryption, more output, energy efficient.

3. L/D( Length to diameter ratio) of 1:15, not easy to deform and long service life, reducing replacement costs

4. Automated machining center production, spinneret detail is perfect.

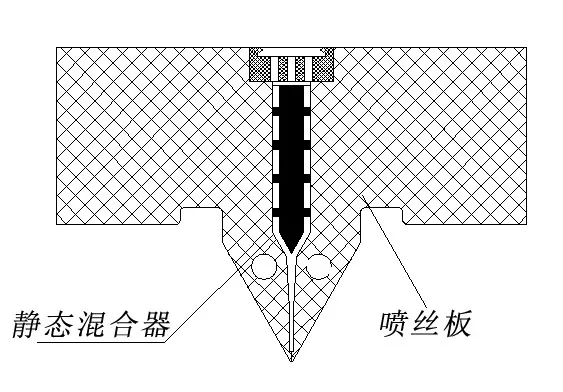

5. Innovative static mixer design for more uniform discharge.

2. Hole number encryption, more output, energy efficient.

3. L/D( Length to diameter ratio) of 1:15, not easy to deform and long service life, reducing replacement costs

4. Automated machining center production, spinneret detail is perfect.

5. Innovative static mixer design for more uniform discharge.

1) :Meltblown Die Head Can be Customized within 100-3200mm

2):Hole size Can be produced ≥0.06mm(0.0024 inch)

3):Tolerance: ±0.002(0.000078inch)

2):Hole size Can be produced ≥0.06mm(0.0024 inch)

3):Tolerance: ±0.002(0.000078inch)

Features

Optimized design, hole number encryption, high output, reduced production costs

The number of holes per spinneret is 13% less than jier. Less of holes, then less of yield.

High-performance Brand Compressor; Mature Technology, Stable performance; Wide Range of Use, Long Service LIfe

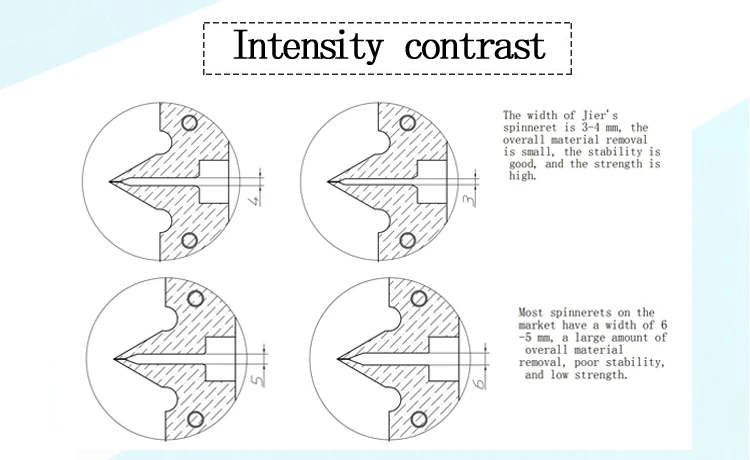

L/D ratio (small hole length): Common 1:10, Our Company 1:15, our length is 50% longer than common spinneret, the top of the spinneret is strengthened, not easy to deform, ordinary hardness HRC (25-28° ),jier hardness HRC (34-38 °) has a longer service life.

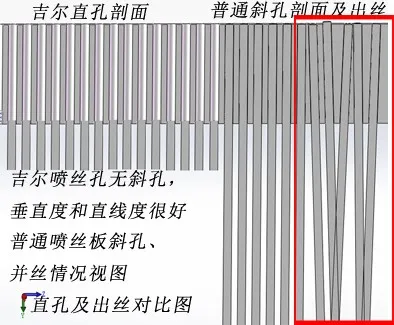

Use CNC high-speed machining centers , the verticality and straightness are good.

Common spinneret use 'Electric spark punching and manual drilling'. Shortcoming: The hole is not straight, multi-slanted hole, hole wall is not smooth, the verticality and straightness are not good. Our company uses CNC high-speed machining center processing, the holes of our product without slanting holes, verticality and straightness is very good, There will be no serious phenomenon of "spot" floating wire caused by merged wire and broken wire.

(Fig. 3-1) is the product straightness of the jier company under the Nikon projector, (Fig. 3-2) is the straightness of the artificial drilling straightness under the same projector.

(Fig. 3-1) is the product straightness of the jier company under the Nikon projector, (Fig. 3-2) is the straightness of the artificial drilling straightness under the same projector.

New baffle design, uniform output, perfect product quality

Due to the structural factors of the conventional spinneret, there is often uneven discharge. Our company adds static mixing deflector to the melt chamber channel for the defects of the spinneret., so that the melt is evenly mixed in all parts of the chamber while the air duct structure data is improved. Make the quality of the products more perfect.

Product Advantages

Melt blown die head

1. Encrypted holes, more output

2. 1:15 aspect ratio, making strength and hardness higher, not easy to deform

3. CNC high-speed machining center processing, the hole wall is smoother and more refined.

4.Innovative design of the deflector, more uniform discharge, better quality silk.

5.Available in a variety of materials, any detail can be customized, meet your needs

2. 1:15 aspect ratio, making strength and hardness higher, not easy to deform

3. CNC high-speed machining center processing, the hole wall is smoother and more refined.

4.Innovative design of the deflector, more uniform discharge, better quality silk.

5.Available in a variety of materials, any detail can be customized, meet your needs

Why Choose Us

Changzhou JIER precision machinery manufacturing Co., Ltd is specializing in the production of various kinds of spray wire plate.We have introduced comprehensive domestic and foreign advanced spray wire plate. For years, through the production process ,technology process and high precision machining testing equipment continuously and automatically innovation and training, together with all staff meticulous work attitude, our spinneret manufacturing level completely meet your requirements of stringent quality of products .

Packing & Delivery

Packing Details : Packing, cardboard box or wooden case

Delivery Details : 30 working days

Delivery Details : 30 working days

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory. And we can supply spinning packs according to your requirements.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for extra charge and do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance, balance after the goods have been manufactured. We will arrange the shipment after your payment.

If you have another question, please feel free to contact us.

If you have another question, please feel free to contact us.

Melt Blown Die,Mould Of Melt Blown Spinnerets,Dense Hole Spinneret,Large Hole Spinneret

Changzhou Jier Precision Machinery Manufacturing Co., Ltd. , https://www.jier-spinneret.com