It is a type of pipe fitting which is utilize to change the flow direction of liquid or gases in the piping system. It is utilize to connect two pipes in order to change the direction of pipe. It can also be used in heat exchangers and other arrangements that demands to flown in the opposite direction. Because its bending angle is very large, it is usually used with 45 Degree Elbow and 90 Degree Elbow.

Table of contents

- What is a 180 Degree Pipe Elbow?

- Stainless Steel 180 Deg Elbow Dimensions Chart

- SS 180° Elbow Short Radius Size Chart

- 180 Deg Elbow Weight Chart

- DIN 2605 Type 3 180 Deg Elbows Pressure Chart

- Stainless Steel 180 Degree Elbow Tolerances Chart

- Temperature Ratings of 2 Inch 180 Degree Pipe Elbow

- Characteristics of 180 Degree Elbows

- Benefits of 180 Degree Alloy Steel Elbow

- Alloy Steel 180° Elbow Applications

What is a 180 Degree Pipe Elbow?

| Size | ERW / Welded / Fabricated Elbow (1/2″~48″), Seamless Elbow ( 1/2″~24″) |

|---|---|

| Dimensions | ASME/ANSI B16.9 / MSS-SP-43 |

| Thickness | Schedule 5S, 10S, 20S, S10, S20, S30, S100, S120, S140, S160,STD, 40S, S40, S60, XS, 80S, S80, XXS and etc |

| Type | Welded / Fabricated / Seamless / ERW |

| Bending Angle | 180 Degree |

| Ends | Bevel / Plain |

| Form | Long Radius / Short |

| Surface treatment | Shot blasted / Rust-proof / Black oil |

| Material | Stainless Steel / Carbon Steel / Nickel Alloy / Alloy Steel |

Check Dimensions and Uses of 180 Degree Steel Pipe Elbow

180 degree steel pipe elbow are utilize for wide range, such as for connection of piping system, abrasion treatment of piping system, for setting up of piping tools, and closing of the piping system.

It is highly utilize when you want to reverse the flow direction totally, by making a U-turn in the pipeline arrangement or system.

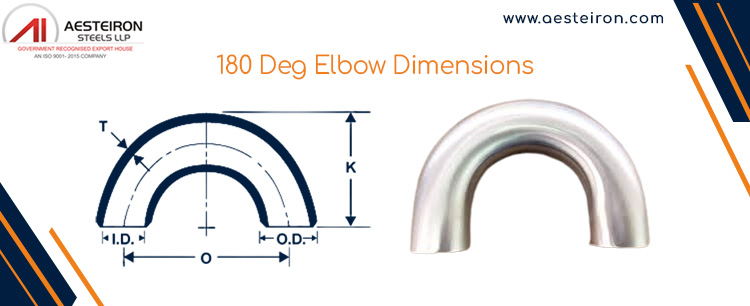

Stainless Steel 180 Deg Elbow Dimensions Chart

| Nominal Pipe Size | Outside DIA | Wall Thickness | Inside DIA | Center To Center | Back To Face | Weight Pounds | Pipe Schedule |

|---|---|---|---|---|---|---|---|

| 1/2 | 0.84 | 0.109 | 0.622 | 3 | 1.88 | 0.32 | 40 |

| 1 1/2 | 1.9 | 0.145 | 1.61 | 4.5 | 3.25 | 1.6 | 40 |

| 2 | 2.38 | 0.154 | 2.067 | 6 | 4.19 | 3.2 | 40 |

| 2 1/2 | 2.88 | 0.203 | 2.469 | 7.5 | 5.19 | 6.1 | 40 |

| 3/4 | 1.05 | 0.113 | 0.824 | 2.25 | 1.69 | 0.34 | 40 |

| 1 | 1.31 | 0.133 | 1.049 | 3 | 2.19 | 0.74 | 40 |

| 1 1/4 | 1.66 | 0.14 | 1.38 | 3.75 | 2.75 | 1.1 | 40 |

| 3 | 3.5 | 0.216 | 3.068 | 9 | 6.25 | 9.4 | 40 |

| 3 1/2 | 4 | 0.226 | 3.548 | 10.5 | 7.25 | 12.8 | 40 |

| 8 | 8.63 | 0.322 | 7.981 | 24 | 16.31 | 87 | 40 |

| 10 | 10.75 | 0.365 | 10.02 | 30 | 20.38 | 164 | 40 |

| 4 | 4.5 | 0.237 | 4.026 | 12 | 8.25 | 17.5 | 40 |

| 5 | 5.56 | 0.258 | 5.047 | 15 | 10.31 | 29.3 | 40 |

| 6 | 6.63 | 0.28 | 6.065 | 18 | 12.31 | 47 | 40 |

| 12 | 12.75 | 0.375 | 12 | 36 | 24.38 | 237 | * |

| 14 | 14 | 0.375 | 13.25 | 42 | 28 | 311 | 30 |

| 16 | 16 | 0.375 | 15.25 | 48 | 32 | 408 | 30 |

| 18 | 18 | 0.375 | 17.25 | 54 | 36 | 514 | * |

| 20 | 20 | 0.375 | 19.25 | 60 | 40 | 636 | 20 |

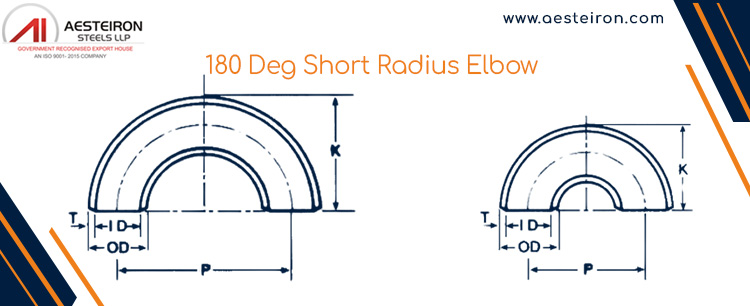

180 Degree Short Radius Elbow Are Available in Size Range of 1/2 to 24 Inch

180 degree short radius elbow is kind of elbow which has smaller radius as compared to usual 180 degree elbow. It acquires radius equal to the pipe diameter, which makes it more compress and beneficial in minimal space. Although, this pipe fitting can give higher resistance to flow which may end up in improved pressure drop.

SS 180° Elbow Short Radius Size Chart

| Nominal Pipe Size (NPS) | Outside Diameter at Bevel OD |

Short Radius Elbow | |

|---|---|---|---|

| Center to Center. P |

Back to Face K | ||

| 1-1/4 | 42.2 | 63.5 | 52.3 |

| 1-1/2 | 48.3 | 76.2 | 62.0 |

| 2 | 60.3 | 101.6 | 81.0 |

| 1/2 | 21.3 | – | – |

| 3/4 | 26.7 | – | – |

| 1 | 33.4 | 50.8 | 41.1 |

| 2-1/2 | 73.0 | 127.0 | 100.1 |

| 3 | 88.9 | 152.4 | 120.7 |

| 3-1/2 | 101.6 | 177.8 | 139.7 |

| 10 | 273.1 | 508.0 | 390.7 |

| 12 | 323.9 | 609.6 | 466.9 |

| 14 | 355.6 | 711.2 | 533.4 |

| 16 | 406.4 | 812.8 | 609.6 |

| 4 | 114.3 | 203.2 | 158.8 |

| 5 | 141.3 | 254.0 | 196.9 |

| 6 | 168.3 | 304.8 | 236.5 |

| 8 | 219.1 | 406.4 | 312.7 |

| 18 | 457.2 | 914.4 | 685.8 |

| 20 | 508.0 | 1016.0 | 762.0 |

| 22 | 558.8 | 1117.6 | 838.2 |

| 24 | 609.6 | 1219.2 | 914.4 |

180 Deg Elbow Weight Chart

| Normal Pipe Size In (Inches) | Elbow Short Radius 180 Deg | Elbow Long Radius 180 Deg | ||||||

|---|---|---|---|---|---|---|---|---|

| Sch 5S | Sch 10S | Sch 40S | Sch 80S | Sch 5S | Sch 10S | Sch 40S | Sch 80S | |

| 1/2 | 0.03 | 0.04 | 0.05 | 0.07 | 0.05 | 0.06 | 0.08 | 0.10 |

| 1 1/4 | 0.09 | 0.13 | 0.17 | 0.12 | 0.13 | 0.20 | 0.25 | 0.35 |

| 3/4 | 0.04 | 0.05 | 0.06 | 0.07 | 0.06 | 0.07 | 0.09 | 0.11 |

| 1 | 0.06 | 0.10 | 0.12 | 0.13 | 0.09 | 0.15 | 0.18 | 0.20 |

| 1 1/2 | 0.12 | 0.20 | 0.27 | 0.33 | 0.18 | 0.30 | 0.40 | 0.50 |

| 2 | 0.20 | 0.33 | 0.47 | 0.60 | 0.30 | 0.50 | 0.70 | 0.180 |

| 4 | 0.180 | 1.35 | 2.65 | 3.180 | 1.40 | 2.00 | 4.00 | 5.180 |

| 5 | 1.95 | 2.40 | 4.35 | 6.50 | 2.180 | 3.60 | 6.50 | 9.70 |

| 2 1/2 | 0.40 | 0.60 | 0.180 | 1.20 | 0.60 | 0.85 | 1.35 | 1.80 |

| 3 | 0.60 | 0.180 | 1.35 | 1.180 | 0.180 | 1.30 | 2.00 | 2.180 |

| 6 | 2.70 | 3.35 | 7.00 | 10.5 | 4.00 | 5.00 | 10.5 | 16.0 |

| 8 | 4.180 | 6.70 | 14.5 | 22.5 | 7.40 | 10.0 | 21.5 | 33.5 |

| 16 | 27.5 | 31.5 | 63.5 | 84.0 | 41.3 | 47.0 | 95.0 | 125 |

| 18 | 34.5 | 39.5 | 80.0 | 105 | 51.8 | 59.0 | 120 | 158 |

| 10 | 9.10 | 11.2 | 25.6 | 35.0 | 13.6 | 16.8 | 38.5 | 52.5 |

| 12 | 15.6 | 18.0 | 39.5 | 53.0 | 23.4 | 27.0 | 59.0 | 79.0 |

| 14 | 19.3 | 23.5 | 47.0 | 63.0 | 29.0 | 35.0 | 70.0 | 94.0 |

| 20 | 49.0 | 57.0 | 98.0 | 129 | 73.0 | 85.0 | 146 | 194 |

| 24 | 82.0 | 94.0 | 140 | 188 | 122 | 140 | 210 | 282 |

DIN 2605 Type 3 180 Deg Elbows Pressure Chart

| Service | Pressure Temperature Limits | Pressure Limits |

|---|---|---|

| gases & vapors, Air | maximam 200oF (93oC), min. 0oF (-18oC) |

150 psig (1000 kPa) |

| condensate & Steam | maximam 366oF (186oC), min. 0oF (-18oC) |

150 psig (1000 kPa) |

| Nonflammable Liquids | maximam 250oF (121oC), min. 0oF (-18oC) |

350 psig (2300 kPa) |

View Tolerance of 180 Degree Elbow as Per ASME B16.9 Standard

180 degree elbow tolerance refers to the allowable limit of modification in its physical sizes, such as in thickness or diameter of the 180 degree elbow or any pipe fitting. ASME B16.9 standard defines the allowable tolerance which ensures that the pipe fitting precisely fit with the piping system or arrangement without negotiating with execution and safety while using the 180 degree elbow fitting.

Stainless Steel 180 Degree Elbow Tolerances Chart

| All fittings | Elbows 180 degree | 180 degree Returns | |||||

|---|---|---|---|---|---|---|---|

| (NPS) | I.D. at End | O.D. at Bevel | Wall Thick. / t1 | Center to End Dim. A-B-C-M | Back to Face Dim.K | Center to Center Dim.O | Align- ment of EndsU |

| 1/2 a 2 1/2 | 0,8 | 1 | Not | 2 | 7 | 7 | 1 |

| 8 | 1,6 | 2 | of nominal | 2 | 7 | 7 | 1 |

| 10 | 3,2 | +4 -3 | tickness | 2 | 7 | 7 | 2 |

| 12 a 18 | 3,2 | +4 -3 | 3 | 7 | 10 | 2 | |

| 3 a 3 1/2 | 1,6 | 1 | less | 2 | 7 | 7 | 1 |

| 4 | 1,6 | +2 -1 | than | 2 | 7 | 7 | 1 |

| 5 a 6 | 1,6 | +3 -1 | 87,50% | 2 | 7 | 7 | 1 |

| 20 a 24 | 4,8 | +6 -5 | 3 | 7 | 10 | 2 | |

| 26 a 30 | 4,8 | +7 -5 | 3 | ….. | ….. | ….. | |

| 32 a 48 | 4,8 | +7 -5 | 5 | ….. | ….. | ….. | |

Temperature Ratings of 2 Inch 180 Degree Pipe Elbow

| Pressure-Temperature ratings for ASME B16.9 fittings (psig) | |||||

|---|---|---|---|---|---|

| Temperature Ratings | Pressure Class | ||||

| 150 | 300 | ||||

| 1 1/4 – 2 inch. | 1/4 – 1 inch. | 2 1/2 – 3 inch. | |||

| (oC) | (oF) | ||||

| -29 to 66 | -20 to 150 | 300 | 1500 | 2000 | 1000 |

| 93 | 200 | 265 | 1350 | 1785 | 910 |

| 121 | 250 | 225 | 1200 | 1575 | 825 |

| 149 | 300 | 185 | 1050 | 1360 | 735 |

| 177 | 350 | 150 | 900 | 1150 | 650 |

| 204 | 400 | – | 750 | 935 | 560 |

| 232 | 450 | – | 600 | 725 | 475 |

| 260 | 500 | – | 450 | 510 | 385 |

| 288 | 550 | – | 300 | 300 | 300 |

Characteristics of 180 Degree Elbows

| Type of Elbow | Angle | Purpose | Common Usage |

|---|---|---|---|

| 90-Degree Elbow | 90 degrees | Connects pipes at a right angle. | Most common for sharp turns in piping systems. |

| 45-Degree Elbow | 45 degrees | Connects pipes at a medium angle. | Provides a smoother transition than the 90-degree elbow. |

| 180-Degree Elbow | 180 degrees | Connects pipes to reverse direction. | Used for creating a U-turn in piping systems. |

Stainless Steel 180 Degree Elbows Are Used to Change the Fluid Direction Flow

It is liable of promoting changes in fluid flow direction. It is used where complete U-turn is required. It makes it frequently utilize for application where liquid or gas are demanded to be divert it into the opposite way.

Benefits of 180 Degree Alloy Steel Elbow

| Aspect | Details |

|---|---|

| Advantage | – No Additional Segments or Fittings: Changes direction without extra parts. |

| – Cost and Time Efficiency: Saves on installation time and expenses. | |

| – Leakage Reduction: Fewer connection points reduce the risk of leakage. | |

| – Reduced Turbulence and Pressure Drop: Smoother flow minimizes turbulence and pressure loss. | |

| Function | – Direction Change: Alters the fluid flow direction in a pipeline. |

| – Pipe Connection: Joins two pipes of the same diameter. | |

| – Flow Adjustment: Provides a 180-degree turn, enabling a complete reversal of flow direction. | |

| Usage | – Applications: Used in various piping systems where a complete change in direction is required. |

SCH 40 180 Deg Elbow Are Widely Used in Oil and Gas and Petroleum Industry

SCH 40, 180 deg elbow has the ability to hold medium stress level while providing effective liquid flow. When 180 deg elbow consist the thickness of Sch 40, will offer good strength which makes it liable to be used at medium pressure and temperature environment. Hence, it is extensively utilize in oil and gas and petroleum industry.

Alloy Steel 180° Elbow Applications

- Oil and Gas Pipeline

- Chemical Industry

- Water Supply Systems

- Power Plant

- Food Processing Industry

- Fabrication Industry

Donaldson is a renowned global leader in filtration solutions for a wide range of industries, offering innovative products that enhance performance, reliability, and efficiency. Founded in 1915 and headquartered in Bloomington, Minnesota, USA, Donaldson serves customers worldwide with a diverse portfolio of filtration solutions designed to meet the stringent demands of various applications.

Categories of Donaldson Products

-

Air Filtration:

- Industrial Air Filters: Donaldson manufactures a comprehensive range of industrial air filters designed to remove contaminants such as dust, dirt, and particulates from air intake systems. These filters are crucial for protecting equipment, improving air quality, and enhancing operational efficiency in manufacturing plants, power generation facilities, and industrial environments.

- Engine Air Filters: Engine air filters play a critical role in maintaining the performance and longevity of engines by preventing harmful contaminants from entering combustion chambers. Donaldson offers a variety of engine air filters for automotive, heavy-duty trucking, construction equipment, and Agricultural Machinery applications.

-

Liquid Filtration:

- Hydraulic Filtration: Donaldson hydraulic filters are designed to protect hydraulic systems from contaminants that can cause equipment failure and downtime. These filters ensure clean hydraulic fluid, thereby optimizing equipment performance and extending component life in construction, mining, and industrial machinery.

- Fuel Filtration: Fuel filters from Donaldson remove water, particulates, and other contaminants from fuel systems, enhancing fuel quality and reliability in diesel engines used in transportation, agriculture, marine, and stationary power applications.

-

Process Filtration:

- Industrial Process Filters: Donaldson offers a range of process filters for applications in pharmaceuticals, food and beverage, electronics, and chemical industries. These filters ensure product quality, regulatory compliance, and operational efficiency by removing impurities and maintaining clean process fluids.

- Compressed Air and Gas Filtration: Compressed air and gas filters play a crucial role in maintaining the quality and reliability of compressed air systems. Donaldson's filters remove moisture, oil, and contaminants, ensuring clean and dry air for various industrial processes and applications.

-

Exhaust and Emissions Solutions:

- Exhaust Gas Filtration: Donaldson develops advanced exhaust gas filtration solutions to reduce emissions of particulate matter and harmful gases from diesel engines and industrial processes. These solutions help meet stringent environmental regulations and improve air quality in urban areas and industrial facilities.

- Catalysts and Aftertreatment Systems: Donaldson offers catalysts and aftertreatment systems that complement exhaust gas filtration, enabling efficient reduction of nitrogen oxides (NOx), carbon monoxide (CO), hydrocarbons (HC), and particulate emissions from diesel engines and industrial sources.

-

Industrial Filtration Systems:

- Dust Collection Systems: Donaldson manufactures dust collectors and filtration systems for capturing and controlling airborne dust and particulates in industrial environments. These systems improve air quality, protect workers' health, and comply with regulatory standards in industries such as metalworking, mining, woodworking, and pharmaceutical manufacturing.

- Mist Collection Systems: Donaldson's mist collectors are designed to remove oil mist, coolant mist, and other aerosols from machining operations, ensuring clean air and maintaining equipment performance and longevity in automotive, aerospace, and metal fabrication industries.

Â

We offer a complete line of fuel filters for mainstream on-highway and off-highway applications.Spin-on and cartridge filters in a wide variety of filter media

Donaldson,Donaldson Hydraulic Oil Filters,Donaldson Hydraulic Filters,Donaldson Hydraulic Filter Cartridge

Shandong Vio Machinery co.,ltd. , https://www.shantui-xcmgparts.com