Building a robotic automation system might seem daunting, but it’s often simpler than you’d imagine. Take, for instance, the creation of a 5-axis SCARA robot using readily available components. This horizontal articulated robot was designed in-house to handle tasks like pick-and-place operations and process-to-process transportation of small parts in limited spaces.

Our SCARA robot serves multiple purposes, including gluing, measuring, and assembling tasks that were traditionally done manually. Conventional robots tend to be bulky and lack the flexibility needed to fit into confined areas. Thus, constructing this SCARA robot allowed us to optimize our workspace significantly.

Below is an overview of the robot’s specifications:

| **Spec** | **Details** |

|----------------------|-----------------------------------------------------------------------------|

| Number of Axes | 5 axes (3 links + lift + electric gripper) |

| Robot Control | MRC01 Robot Controller |

| Payload | 0.7 kg |

| Maximum Speed | 500 mm/s (at the gripper tip) |

| Maximum Speed per Axis| Axis 1: 500 mm/s, Axis 2: 500 mm/s, Axis 3: 500 mm/s, Axis 4: 40 mm/s, Axis 5: 156 mm/s (both sides) |

| Main Power | 115 VAC |

| Drive/Control Power | 24 VDC |

| Mass | 4 kg |

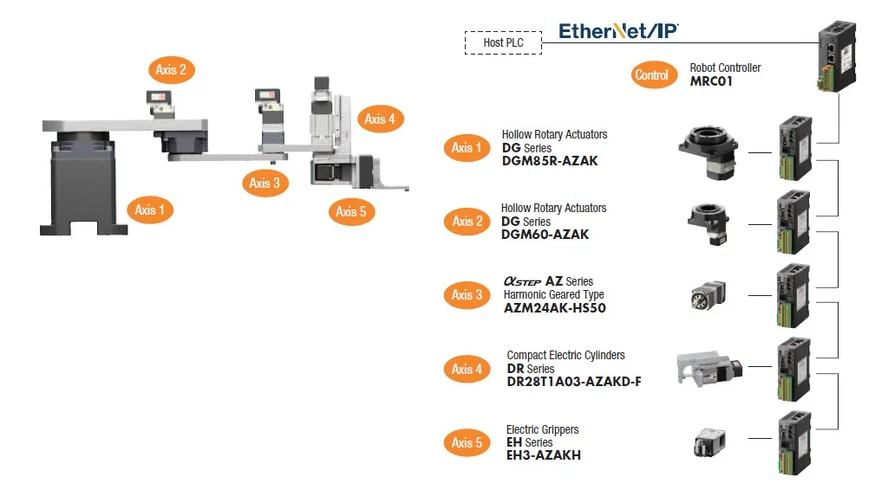

### System Configuration

The SCARA robot operates via Ethernet/IP from a host controller, such as a PLC. The MRC01 robot controller communicates with all AZ Series drivers through RS-485 communication (Modbus RTU).

### Component List

| Axis | Image | Component | Product Name |

|---------------------|-----------------------------|-------------------------------|----------------------------|

| Axis 1 | [Image](link) | Hollow Rotary Actuator | DGM85R-AZAK |

| | | Driver | AZD-KD |

| | | Flexible Connection Cable | CC030VZR2 |

| | | DC Power Cable | CC02D010-3 |

| | | RS-485 Communication Cable | CC001-RS4 |

| Axis 2 | [Image](link) | Hollow Rotary Actuator | DGM60-AZAK |

| | | Driver | AZD-KD |

| | | Flexible Connection Cable | CC030VZ2R2 |

| | | DC Power Cable | CC02D010-3 |

| | | RS-485 Communication Cable | CC001-RS4 |

| Axis 3 | [Image](link) | αSTEP Harmonic Geared Type | AZM24AK-HS50 |

| | | Driver | AZD-KD |

| | | Flexible Connection Cable | CC030VZ2R2 |

| | | DC Power Cable | CC02D010-3 |

| | | RS-485 Communication Cable | CC001-RS4 |

| Axis 4 | [Image](link) | Compact Cylinder | DR28T1A03-AZAKD-F |

| | | Driver | AZD-KD |

| | | Flexible Connection Cable | CC030VZ2R2 |

| | | DC Power Cable | CC02D010-3 |

| | | RS-485 Communication Cable | CC001-RS4 |

| Axis 5 | [Image](link) | Compact Gripper | EH3-AZAKH |

| | | Driver | AZD-KD |

| | | Flexible Connection Cable | CC030VZ2R2 |

| | | DC Power Cable | CC02D010-3 |

| | | RS-485 Communication Cable | CC001-RS4 |

| Controller | [Image](link) | Robot Controller | MRC01 |

| | | DC Power Cable | CC02D010-3 |

| | | RS-485 Communication Cable | CC001-RS4 |

The total estimated cost for building this SCARA robot is approximately $11,969. In contrast, purchasing a standard 5-axis SCARA robot within these specifications could cost anywhere from $15,000 to $25,000. This represents a potential savings of up to $13,031 when opting for an in-house solution.

### Key Benefits of MRC01 and MRC Studio

The MRC01 robot controller and its accompanying MRC Studio software offer several advantages:

- **Ease of Integration**: The MRC01 allows seamless linkage with existing systems via EtherNet/IP, enabling smooth integration without significant modifications.

- **User-Friendly Setup**: Even first-time users can configure and operate the robot without advanced programming knowledge. A wizard guides users through essential steps like selecting robot types and inputting mechanism details.

- **Simulation Capability**: You can test the operation program using an online 3D simulator before running the actual motor, minimizing errors and risks.

- **Versatility**: The MRC01 supports various robot configurations, including vertical articulated robots, SCARA robots, and orthogonal robots, offering flexible design options.

- **Rich Compatibility**: It works seamlessly with AZ series actuators and motors, ensuring a high degree of customization.

For those looking to design their own robots, our team offers assistance in motor sizing and selection. Simply download our selection request form, fill it out, and submit it to us along with any relevant schematics or CAD data.

---

While creating this SCARA robot proved to be both efficient and cost-effective, there are numerous other considerations when designing robotic systems. Our team is always ready to provide additional resources and support tailored to your specific needs. Whether you’re looking to integrate a parallel-link robot or another type of system, feel free to reach out to us for guidance. We’re here to help every step of the way!

Custom Made Sheet Metal,Industrial Sheet Metal Services,Precision Sheet Metal,Precision Sheet Metal Fabrication Services

Ningbo Jiongke Technology Co., Ltd , https://www.processingmfg.com