| Product Name | SMT Machine YAMAHA Nozzle |

| Installation | Vertical |

| Driven Type | Pneumatic |

| Customized | Accept |

Related Products:

We offer a complete range of SMT machine parts including nozzles, feeders, and spare components for major brands like Fuji, JUKI, Samsung, Yamaha, and Panasonic. Whether you need pick-and-place machine parts, PCB conveyor belts, or pneumatic cylinders, we have the right solution for you. Our products are designed for high performance and durability in automated manufacturing environments.

Our main product lines include:

- 1. SMT Lubricating Oil

- 2. SMT Spare Parts

- 3. Nozzles and Feeders

- 4. SMT Belts and Other Internal Components

Company Information:

Our company is a professional manufacturer specializing in high-quality SMT machine parts and accessories. We focus on providing reliable, durable, and cost-effective solutions to meet the needs of our global customers. With strict quality control and a commitment to innovation, we ensure that every product meets international standards. Our goal is to deliver excellent service and support, helping you maintain optimal performance in your production line.

FAQ:

FAQ:1. Q: Are you a factory or a trading company?

A: We are a direct manufacturer with full control over production and quality. This allows us to offer competitive pricing and high-quality products.

2. Q: Can I get free samples?

A: Samples are available but require payment. However, we can provide samples at a reduced cost upon request.

3. Q: What shipping options do you offer?

A: We usually ship via air freight for faster delivery, but sea freight is also available for bulk orders.

4. Q: What are your testing standards?

A: All products are tested according to international standards to ensure reliability and performance.

5. Q: Do you accept OEM or ODM?

A: Yes, we accept OEM and ODM orders. Our R&D team is experienced in customizing products to meet specific client requirements.

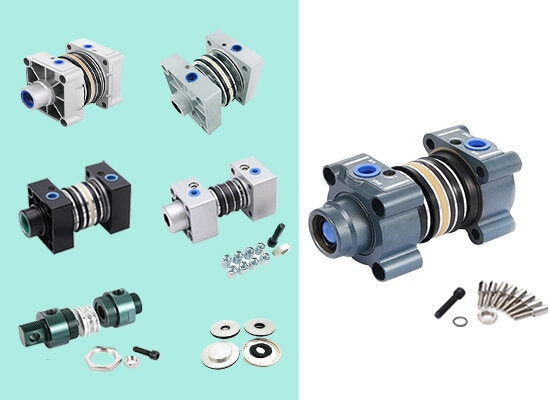

Cylinder assembly accessories include one front cover and one rear cover, one piston, two Y-type piston seals, one hard-wearing ring, one set of magnetic rings (some cylinders do not have magnetic rings), two cylinder seal O-rings, one piston rod sealing ring, one dustproof, two buffer caps, two buffer screws (with O-ring), one piston rod end thread, one piston fixing bolt, 8 fixing bolts, dustproof air inlet and outlet two caps, one piston rod end thread protection cover.Air Cylinder Tube.

Because the different application needs different strokes of air cylinders, for dealers and distributors, storing a large number of cylinders with fixed strokes will occupy a large amount of inventory funds.Pneumatic Cylinder Tube.

However, storing the Pneumatic Cylinder assembly parts can solve this problem very well. When requires different strokes and then temporarily assembling the cylinder accordingly.Air Cylinder Barrel.

Categories

Common cylinder assembly parts include DNC square cylinder series, ISO standard Metalwork series, SI Mickey Mouse type ISO 15552 cylinder series, SC and SU AirTac standard cylinder series, SDA compact cylinder series, and DSN, MA, MAL mini air cylinder series, etc. .

Matters needing attention when assembling the cylinder

For non-professional cylinder manufacturers, we do not recommend self-assembly to avoid problems caused by incorrectly assembling cylinders.

The following points need to be paid attention to when assembling an air cylinder by yourself:

â—† The inner edge of a pneumatic cylinder needs to be chamfered to facilitate the entry of the piston and sealing ring into the cylinder tube.

â—† Before assembling the piston and cylinder, lubricating grease must be applied to the inner wall of the cylinder to reduce the friction between the sealing ring and the inner wall of the air cylinder.Pneumatic Cylinder Barrel.

â—† The edge of the piston rod end also needs to be chamfered to reduce damage to dust and buffer seals.Pneumatic Cylinder.

â—† Because the end of the piston rod has external threads, special attention should be paid when assembling the piston rod and the front end cover. It is necessary to use the end of the piston rod without threads to pass through the gasket. Otherwise, the inner wall of the gasket is easily cut by the threads and resulting in an air leakage.

â—† For the installation of the tie rod cylinder, it is also necessary to pay attention to the position of the tie rod thread, so that there is enough thread space in the fixing bolts of the front and rear end covers to install the cylinder accessories such as CA, CB mounting brackets, FA/FB flange brackets.Cylinder Tube.

Pneumatic Cylinder Kits,Air Cylinder Kits,Pneumatic Air Cylinder Kits,Aluminum Cylinder Kits

Foshan Weiyingjia Technology Co., Ltd , https://www.wyspneumatic.com