1 Specifications

NO. |

Items |

Specification & Details |

1 |

Material |

Carbon steel, stainless steel, brass or as per customer's requirements. |

2 |

Diameter |

0.3–17 mm, tolerance: ±0.001 mm |

3 |

Roundness |

0.001 mm |

4 |

Roughness |

Ra0.04 |

5 |

Straightness |

0.001 mm |

6 |

Hardness |

HRC/HV |

7 |

Precision |

Grade 6 |

8 |

Length |

Max. 1000 mm |

9 |

Heat treatment |

Point hardening, quenching hardening |

10 |

Surface treatment |

Zinc plating, nigrescence, chrome plating, nickel plating, etc. |

11 |

OEM Service |

Provide us with your drawing and detailed specifications. |

12 |

Packaging |

Plastic bag inside and outer standard carton, pallet. Custom packaging available upon request. |

2 Photos

3 Company Show

4 Main Products

Changzhou Shnmotor is a developing manufacturing and trading company focused on electrical products for the refrigeration market. With a highly qualified team and over eight years of experience in machinery design, manufacturing, management, and customer service, we ensure quality and innovation at every stage. Our ISO 9000 certification and 6S management system guarantee strict quality control across all processes.

Our main products include:

1) Brushless DC Motor

2) Stepping Motor

3) AC Motor

4) Motor Group (Motor + Reducer + Driver + Brake)

5) Shafts

5 Packing & Delivery

6 Application

CNC machines: engraving machine, milling machine, coiling machine, sparking machine, wire-electrode cutting, and more.

Electronic equipment: up-coiler, stripping machine, lithium battery production equipment, dispensing machine, and more.

Packaging equipment: filling machine, fixed-length cutting machine, tissue paper machine, paper diaper equipment, and more.

Textile equipment: flat knitting machine, hosiery machine, embroidery machine, spinning machine, knitting machine, and more.

Laser machines: screen printing machine, pad printing machine, and more.

Printing equipment: carving machine, cutting machine, labeling machine, and more.

Others: robots, unmanned aerial vehicles, and more.

7 Buyer’s Guide

1. Motors Production

All the products sold here are manufactured by CZSHN Motors and Electric Appliance Factory in Changzhou, Jiangsu Province, China.

2. Motors and Shaft Selection

Please contact us to confirm the model and other details before purchasing.

3. Payment

We can provide samples and accept full prepayment only. For bulk orders, 50% advance payment is required, with the balance paid before shipment. PayPal, Western Union, and T/T are all accepted.

4. Delivery

Samples in stock can be delivered within 7 days, while customized samples may take up to 30 days. Delivery time for bulk orders depends on the quantity.

5. Feedback and After-Sale Service

If you encounter any issues during use, please let us know! Our technicians will provide professional advice. We offer free maintenance within 24 months if the defects are due to production.

FAQ

Q: How to choose a model that matches my machine?

A: Please provide the key parameters of the product. Feel free to contact us and give the information—we’re happy to help if you're confused about selection.

Q: If I need a special model, can you manufacture it?

A: Yes, we can. Send us a drawing or sample, and we’ll find a suitable replacement. Or, describe your application to our engineers, and we’ll work together to create a custom solution.

Q: Do you have any products in stock? Can I order samples first?

A: We stock many standard models. If you’d like to test a sample first, we’re glad to send some your way. However, we don’t stock specialized motors. Let us know your needs, and we’ll do our best to send samples as soon as possible.

Q: How long should I expect the lead-time/delivery to be?

A: For standard model samples, we can usually ship them within 15 days by air. For custom motors, allow 4–5 weeks.

Q: How are your products delivered?

A: We are flexible with shipping and work with most major courier services worldwide. When placing an order, just provide a shipping address and contact info—we’ll handle the rest. If you prefer a specific forwarder or courier, let us know, and we’ll accommodate.

Q: What about the quality of your motors?

A: Delivering quality products is our top priority. We have testing procedures throughout the manufacturing process, starting from individual components. If you need a specialized motor, we also add custom testing solutions. In rare cases of issues, we’ll work with you to resolve them promptly and transparently.

Q: Can you provide OEM services? Can I request my own logo?

A: Yes, we can provide OEM services for volume production. Feel free to talk to us about your branding needs.

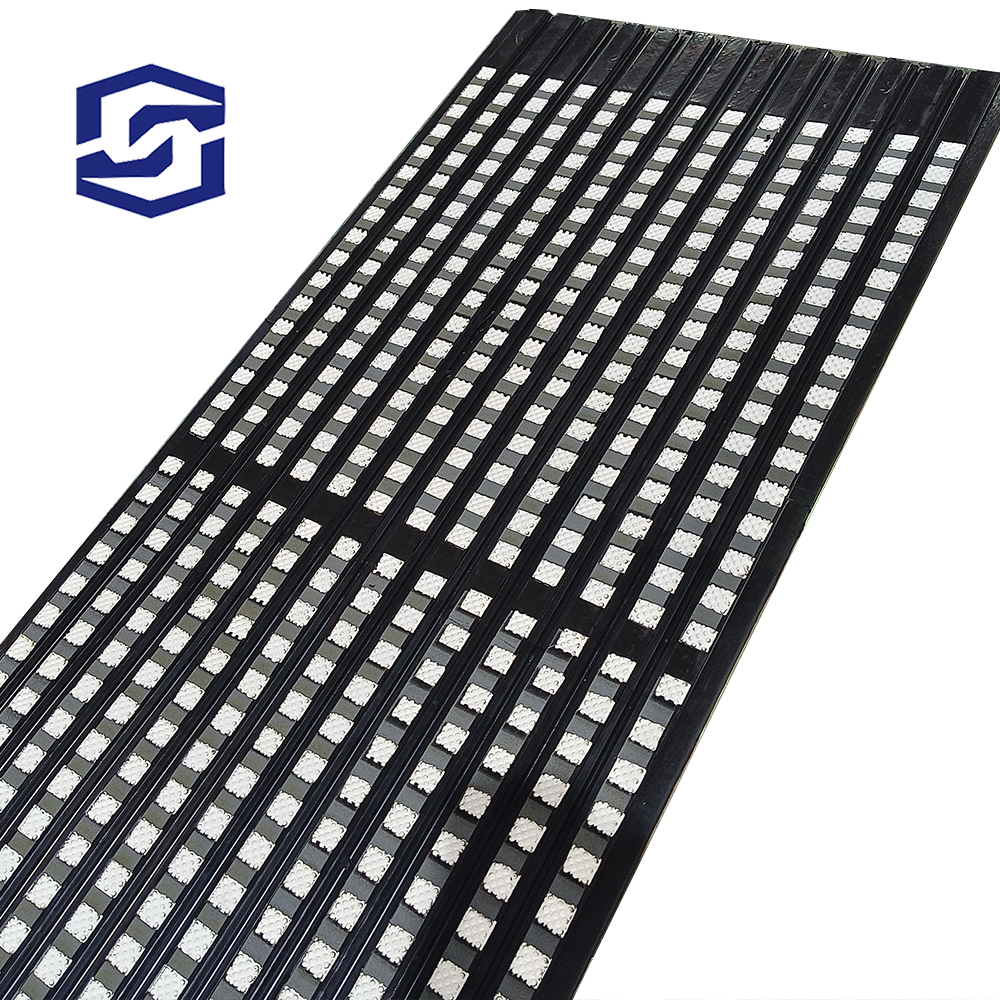

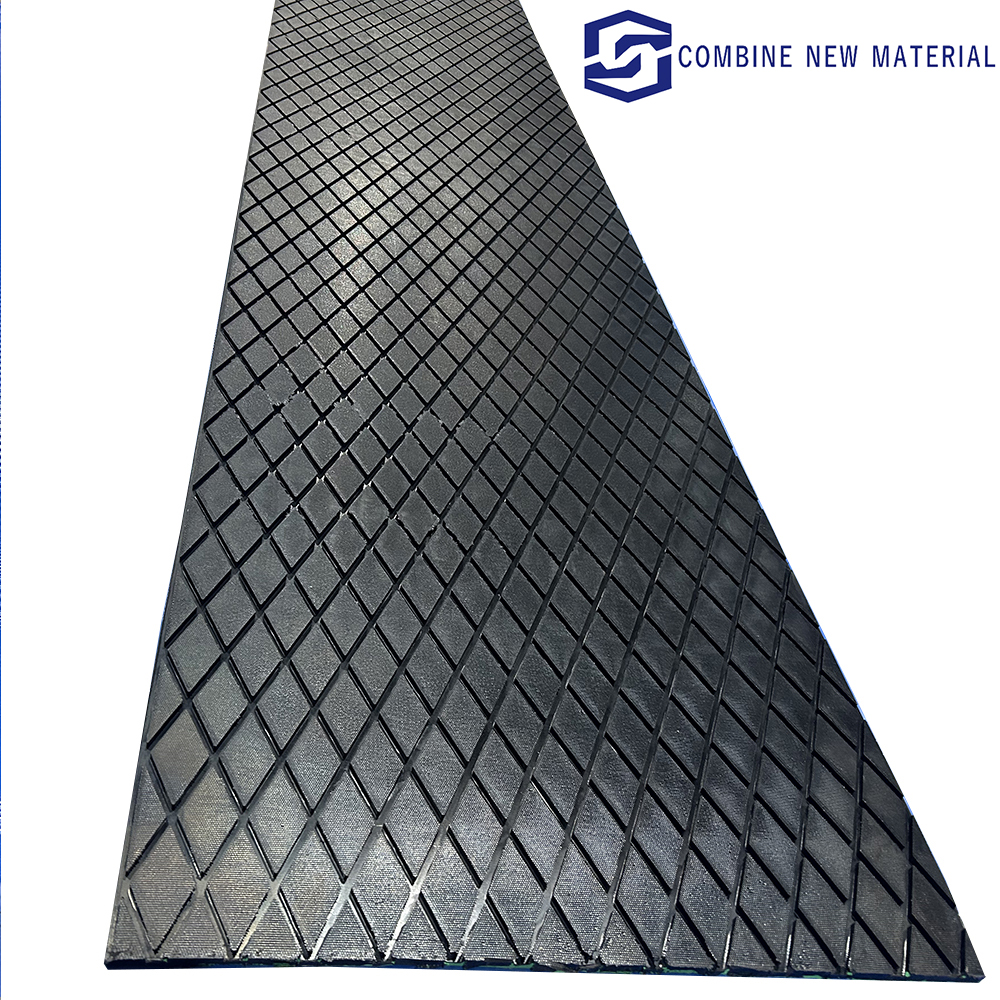

pulley lagging,rubber sheet,wear resistant,ceramic rubber sheet,Three-in-one impact resistant ceramic composite liner

Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com