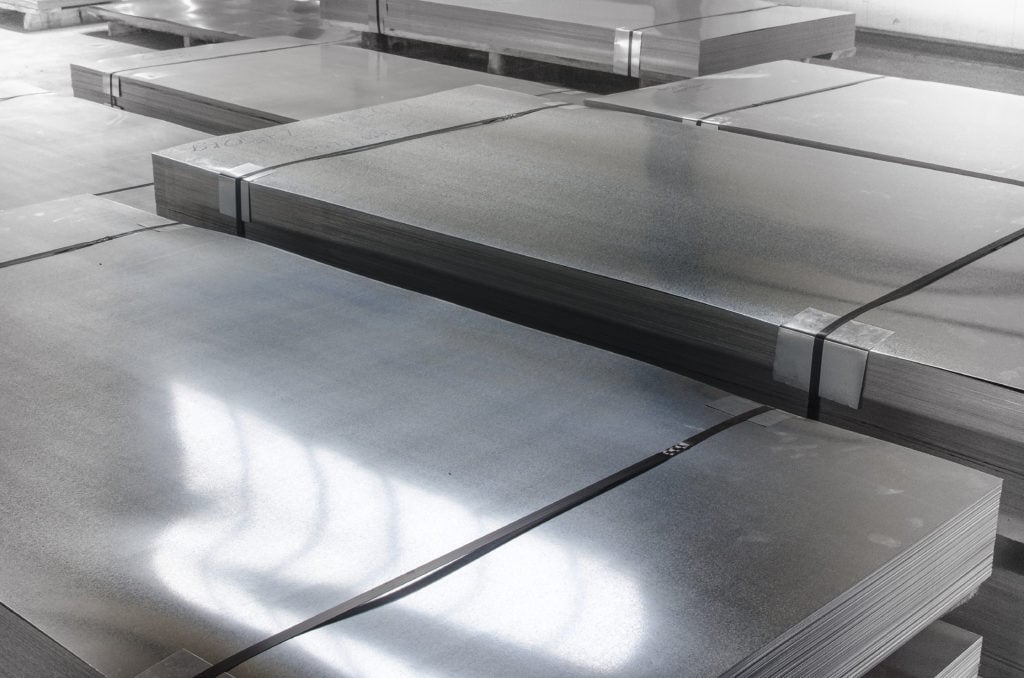

Throughout 2021, the global market has witnessed a sharp rise in prices for key materials like steel, stainless steel, copper, and other base metals. This trend has not only affected manufacturers but also reshaped how companies approach production and sourcing. At ESI, we’ve adapted to these fluctuations, helping our clients develop sustainable and cost-effective metal solutions that stand the test of time.

Our deep experience with various metals has given us valuable insights into how price volatility impacts business operations. From supply chain challenges to shifting trade policies, we’ve seen firsthand how these factors influence project timelines and budgets. Understanding these dynamics allows us to provide smarter, more strategic advice to our customers.

Why Are Metal Prices Rising?

A recent article in the New York Times highlighted that steel, stainless steel, aluminum, and copper are at record highs. Several key factors have contributed to this surge:

1. Tariffs and Reshoring Efforts

The U.S. government’s push to reduce imports through tariffs has led to increased material costs. Companies are now focusing on consolidating and bringing manufacturing back home. For instance, aluminum importers face shortages from Canada, while demand for copper and nickel is surging due to growth in energy storage and electric vehicles. These changes are creating job opportunities across the American economy.

This shift accelerated during the pandemic, and even though some shipping issues have eased, many tariffs remain in place. As a result, prices continue to climb despite logistical challenges like truck driver shortages and rising freight costs.

2. Pandemic-Related Supply Chain Disruptions

Supply chain problems worsened during the pandemic, causing raw material shortages for businesses trying to ramp up production. Freight costs are now at an all-time high, with China’s top 10 ports reporting a 126% increase in D&D charges, according to reports.

Domestically, the shortage of truck drivers—exacerbated by the pandemic and booming e-commerce—has created what Uber Freight’s logistics head calls a “shipping Armageddon.†These delays are extending lead times and making it harder to manage production schedules.

3. Global Capacity Challenges

The combination of higher demand and limited supply has made it difficult to quote pricing and lead times for manufacturing projects. As industries recover and ramp up production, especially in renewable energy and infrastructure, the pressure on metal markets is expected to grow.

With a renewed focus on clean technology and large-scale infrastructure projects in the U.S. and China, the outlook for metal prices remains strong. This creates a perfect storm for continued price increases in the near future.

Which Metals Are Most Affected?

While most metals are experiencing some level of price pressure, the most commonly used industrial metals are seeing the biggest increases. Here’s a breakdown of the main ones:

- Steel & Stainless: Consolidation and reduced scrap availability are driving up production costs.

- Aluminum: Canada, the main supplier for the U.S., has imposed export limits, leading to higher prices due to limited availability.

- Copper: High demand from EVs, electronics, and renewable energy continues to keep prices elevated.

How to Select the Right Material for Your Stamped Metal Part: Learn more here

When Will Prices Drop?

Although metal prices are expected to eventually decline as the global economy recovers, they are unlikely to return to pre-pandemic levels soon. With major infrastructure plans in the U.S. and China keeping demand high, the market may stay tight into 2022.

Additionally, ongoing shipping challenges could lead to longer lead times for certain materials. To prepare, we recommend planning with extra months added to your production schedule in 2022.

Stay Competitive with Cost-Efficient Metal Products from ESI

Due to sourcing uncertainties and delayed lead times, it's essential to understand how material choices can affect both cost and delivery. At ESI, we work closely with our vendors to secure materials and offer alternative designs that help reduce costs or speed up production without compromising quality.

Our 30 years of experience allow us to stay ahead of market trends and provide real-time insights. Whether you're looking for cost savings or faster turnaround, our team is here to help you navigate the current landscape.

To learn more about our metal products and services, contact us today and let us help you make informed decisions for your next project.

{ "@context": "https://schema.org", "@type": "FAQPage", "mainEntity": [{ "@type": "Question", "name": "When Will Metal Prices Drop and Lead Times Stabilize?", "acceptedAnswer": { "@type": "Answer", "text": "Over the course of 2021, the market has seen prices for steel, stainless steel, copper, and other popular base metals rise significantly. Fortunately, ESI has learned how to work with market fluctuations to create sustainable, cost-effective metal products for our customers. Our extensive experience working with a variety of metals also gave us an inside look at the effects that fluctuating metal prices can have on the overall cost of business operations." } },{ "@type": "Question", "name": "Why is the price of metal increasing?", "acceptedAnswer": { "@type": "Answer", "text": "According to a recent article published in the New York Times, prices for steel, stainless steel, aluminum, and copper are at record highs. There are three primary reasons for the price increase in our post-COVID economic recovery period." } },{ "@type": "Question", "name": "Which metals are affected?", "acceptedAnswer": { "@type": "Answer", "text": "While supply shortages and high demand are affecting almost every metal market, the metals most frequently used in industrial production are the most affected. Manufacturers can expect to see increases in steel, aluminum, copper, and nickel especially." } }] }

Dewaxing Machine,Wax Processing Machine,Electric Wax Mixing Barrel,Automatic,Dewaxing Machine

Dongying Fuhao Precision Casting Science & Technology Co.,Ltd , https://www.fh-cast.com

Comments are closed