Inspectors in the field of Non-Destructive Testing (NDT) today rely on a variety of tools to gather data remotely.

These tools are commonly known as Remote Visual Inspection (RVI), a term that reflects the ability to collect information from a distance.

The main type of data collected by inspectors is visual—such as images and videos showing the condition of critical parts of an asset, with the goal of identifying potential defects that may require further investigation or maintenance.

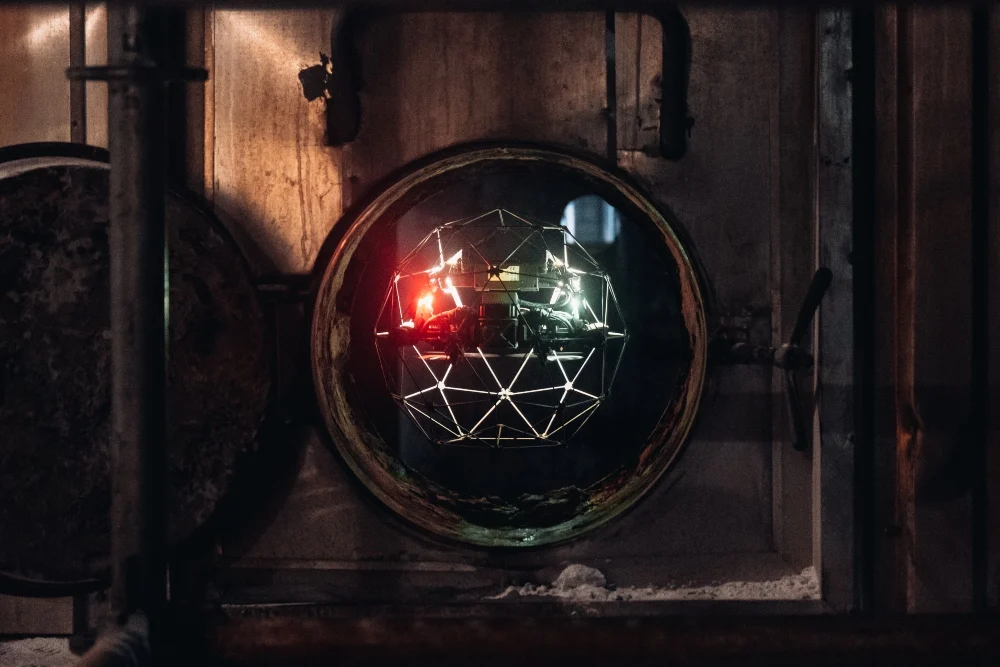

An RVI tool can range from something highly advanced like Flyability’s Elios 2 drone (seen above) for internal inspections, to just a simple camera suspended on a rope.

Regardless of the tool used, the main objective of RVI in indoor inspections—such as those of boilers, pressure vessels, chimneys, or other assets requiring access—is to allow inspectors to collect data safely without entering hazardous environments or standing on scaffolding inside them.

Among the many RVI tools available, indoor drones offer several distinct advantages for NDT. Here are the top seven benefits you should know about.

What Is NDT?

Non-Destructive Testing (NDT) refers to a set of inspection techniques that enable inspectors to collect data about an asset or material without causing any damage.

Visual data is the most common form of data collected during NDT, but inspectors may also use other methods such as ultrasonic testing or radiography to gain deeper insights.

The 7 Major Benefits of Indoor Drones for NDT in Indoor Inspections

1. Enhanced Safety

Indoor inspections often involve three primary risks for inspectors: falling, getting trapped, and exposure to harmful gases.

In some industries, like grain bin inspections, there's an additional risk of being buried under grain if someone falls in. Regardless of the specific scenario, using a drone can eliminate these dangers entirely.

Instead of sending an inspector into a confined space, modern indoor drones like the Elios 2 can collect high-quality visual data remotely, making it unnecessary for humans to enter hazardous areas. This significantly improves safety during the entire inspection process.

[Related reading: What Is the Hierarchy of Control?]

2. Cost Savings & ROI

Using drones for visual NDT instead of sending personnel can lead to significant cost savings for companies.

Here are the main ways businesses benefit financially:

- No need for scaffolding. Setting up and dismantling temporary structures like scaffolding can be extremely expensive, sometimes costing tens or even hundreds of thousands of dollars per inspection. Drones eliminate this expense entirely.

- Reduced downtime. Installing and removing scaffolding is time-consuming, which means using a drone can cut down inspection time, minimizing revenue loss due to asset unavailability.

- Lower liability insurance costs. Since drones reduce the risk associated with human entry into confined spaces, some companies have been able to lower their liability insurance premiums.

Case studies show how much can be saved using indoor drones:

- $2 million saved using the Elios 2 for oil tanker cargo inspections

- $420,000 saved using the Elios 1 by an Argentine energy company, leading to investment in the Elios 2

3. More Frequent Inspections

Drones provide a cost-effective solution for visual NDT, allowing companies to conduct more frequent inspections over time while still saving money.

Increased inspection frequency helps extend the life of assets by catching defects early, preventing them from worsening. It also supports sustainability efforts. A study by Boiler Room Consulting found that using drones for boiler inspections could reduce CO2 emissions by up to 649 metric tons annually.

4. Accurate Data Localization

When it comes to fixing defects found during an inspection, knowing exactly where they are located is crucial.

Flyability’s Inspector 3.0 software allows inspectors to pinpoint defect locations using a sparse point cloud, giving precise spatial data on where each issue was found. This makes it easier for maintenance crews, site managers, and stakeholders to understand where work needs to be done quickly and efficiently.

5. Historical Record Keeping

Unlike manual inspections that only capture video and images of visible defects, drone flights record the entire asset during the mission.

This creates a detailed historical record of the asset’s condition at a specific point in time. The data can also be converted into 3D models or point clouds, offering even more insight into the asset’s state. Such records are invaluable for accident investigations or tracking the progression of defects over time.

6. Better Access to Hard-to-Reach Areas

In some cases, human entry into an asset is not possible, but a drone like the Elios 2 can easily navigate tight spaces.

Examples include:

Sewer inspections

Some sewer systems contain dangerous gases or fast-moving water, making it unsafe for humans to enter. Drones can access these areas and collect visual data without putting people at risk.

Wind turbine inspections

Inspecting wind turbine blades is often limited by physical access and legal restrictions. Drones can fly beyond these limitations, providing more detailed data than traditional methods.

Bridge inspections

Some bridges have tight spaces between beams or box girders that are difficult for inspectors to reach. Drones can access these areas, enabling a more thorough inspection.

Caged drones like the Elios 2 are especially useful in these situations, allowing inspectors to collect visual data from spaces that would otherwise be inaccessible.

7. Higher Quality Data

Modern drone technology provides a visual record of an inspection through video footage, which can be reviewed later to monitor changes in an asset over time.

New software tools can extract accurate measurements from this data, improving the quality of the information collected and creating a more comprehensive historical record of the asset’s condition. This enables better decision-making and long-term asset management.

VBR packer, ram rubber packing elements, xinwei VBR packer

Sichuan Xinwei Rubber Co., Ltd , https://www.boprubber.com