Inspectors in the field of Non-Destructive Testing (NDT) today rely on a variety of tools to gather data remotely.

These tools are commonly known as Remote Visual Inspection (RVI), which refers to the ability to collect information from a distance. This approach allows inspectors to evaluate the condition of critical components without physical entry into hazardous or hard-to-reach areas.

Typically, the data collected through RVI is visual—such as images and videos that show the state of an asset. The goal is to detect potential defects that might require further investigation or maintenance.

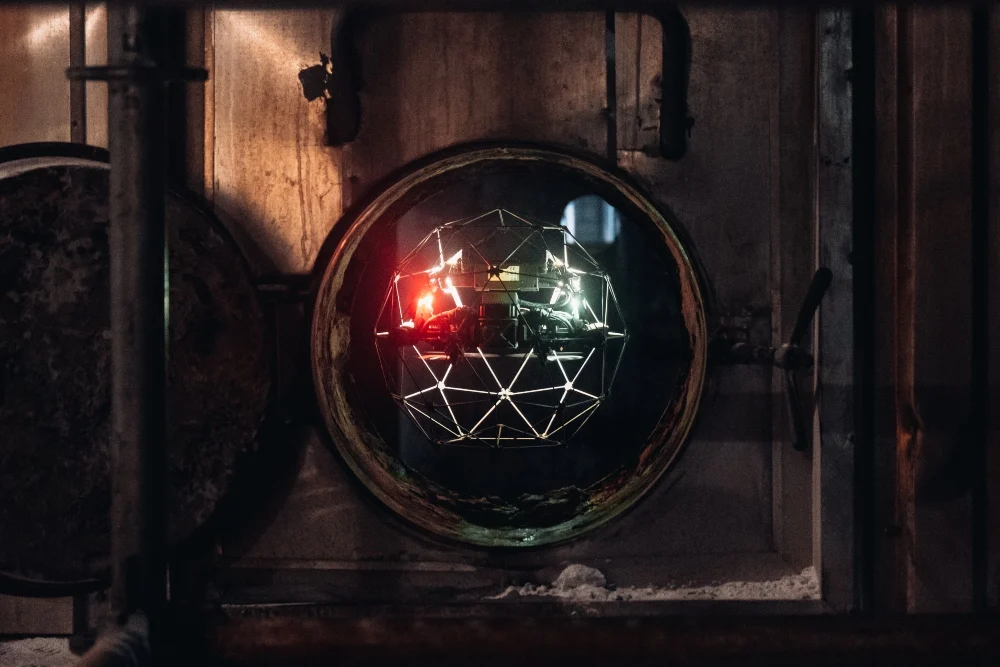

An RVI tool can range from a simple camera attached to a rope to advanced systems like Flyability’s Elios 2 drone, which is specifically designed for internal inspections. These devices enable inspectors to gather high-quality visual data from within complex or dangerous environments.

The main advantage of using RVI during indoor inspections—such as those conducted in boilers, pressure vessels, or chimneys—is that it allows inspectors to collect necessary data without exposing themselves to risks associated with entering confined spaces or standing on scaffolding inside them.

Among all the RVI tools available, indoor drones offer several key advantages. Here are the top seven benefits of using drones for NDT in indoor inspections.

What Is NDT?

Non-Destructive Testing (NDT) involves various inspection techniques that allow professionals to assess the condition of an asset or material without causing any damage. Visual data is the most commonly collected type in NDT, but other methods such as ultrasonic or radiographic testing may also be used depending on the situation.

The 7 Major Benefits of Indoor Drones for NDT in Indoor Inspections

1. Improved Safety

Indoor inspections often involve significant risks, including falling, getting trapped, or exposure to harmful gases. In some industries, like grain bin inspections, there's even a risk of drowning if someone falls into the grain.

Drones eliminate these dangers by allowing inspectors to collect visual data remotely. For example, the Elios 2 drone can replace the need for human entry, providing high-quality video that makes manual inspection unnecessary. By reducing the need for people to enter confined spaces, drones significantly enhance safety during inspections.

[Related reading: What Is the Hierarchy of Control?]

2. ROI & Savings

Using drones for visual NDT instead of sending personnel can lead to substantial cost savings for companies. Here are the main ways drones help reduce expenses:

- No scaffolding required. Setting up and dismantling scaffolding can be extremely costly, sometimes reaching tens or even hundreds of thousands of dollars. Drones eliminate this need, saving companies significant amounts of money.

- Reduced downtime. Installing and removing scaffolding is time-consuming, which can delay operations. Drones speed up the process, reducing the time assets are offline and minimizing revenue loss.

- Lower liability insurance costs. Since drones reduce the risk to human inspectors, some companies have been able to lower their liability insurance premiums by adopting drone-based inspections.

Several case studies demonstrate the financial benefits of using indoor drones. For instance, one company saved $2 million using the Elios 2 for oil tanker cargo inspections, while another saved $420,000 with the Elios 1 and later invested in the Elios 2.

3. Increased Frequency of Inspections

Drones provide a cost-effective solution for visual NDT, allowing companies to conduct more frequent inspections over time. More regular checks can help identify defects earlier, preventing them from worsening and extending the life of the asset.

In addition, increased inspection frequency can contribute to environmental sustainability. A study by Boiler Room Consulting found that using drones to inspect boilers could reduce CO2 emissions by up to 649 metric tons annually.

4. Data Localization

When a defect is found during an inspection, knowing its exact location is crucial. Flyability’s Inspector 3.0 software enables precise localization of defects, providing a sparse point cloud that shows exactly where each issue was detected.

This feature enhances the inspection process by giving all stakeholders—inspectors, maintenance crews, site managers, and others—a clear understanding of where work is needed. It streamlines communication and improves decision-making.

5. Providing a Historical Record

Unlike traditional manual inspections, which may only capture video and still images, a drone flight records the entire asset during the mission. This creates a detailed historical record of the asset’s condition at a specific point in time.

Additionally, the data can be converted into 3D models or point clouds, offering even more detailed insights into the asset’s status. This record is invaluable for investigating accidents or tracking the progression of defects over time.

Drones make it possible to maintain a comprehensive history of key assets, helping companies monitor and manage their infrastructure more effectively.

6. Improved Access within Assets

In many cases, manned entry cannot reach certain parts of an asset, but an indoor drone like the Elios 2 can access these areas. For example:

Sewer inspections: Some sewer systems contain dangerous gases or fast-moving water that make human entry unsafe. A drone can enter and collect visual data from a safe distance, enabling inspections that would otherwise be impossible.

Wind turbine inspections: Inspectors often face limitations in how far they can enter a turbine due to both physical constraints and safety regulations. Drones can fly beyond these limits, capturing more detailed data on blade conditions than manual methods ever could.

Bridge inspections: Tight spaces between beams and girders can make it difficult for inspectors to access certain areas. Caged drones like the Elios 2 can navigate these spaces, providing access that would otherwise be unattainable.

7. Higher Quality Data

Modern drone technology provides a complete visual record of an inspection, captured as video. This data can be saved and reviewed later, allowing inspectors to track changes in an asset over time.

New software tools now help extract accurate measurements from drone data, improving the quality of the information collected. This leads to a more thorough and reliable historical record of an asset’s condition, which can be referenced at any time.

VBR packer, ram rubber packing elements, xinwei VBR packer

Sichuan Xinwei Rubber Co., Ltd , https://www.boprubber.com